Call Us

86-755-82924037

Call Us

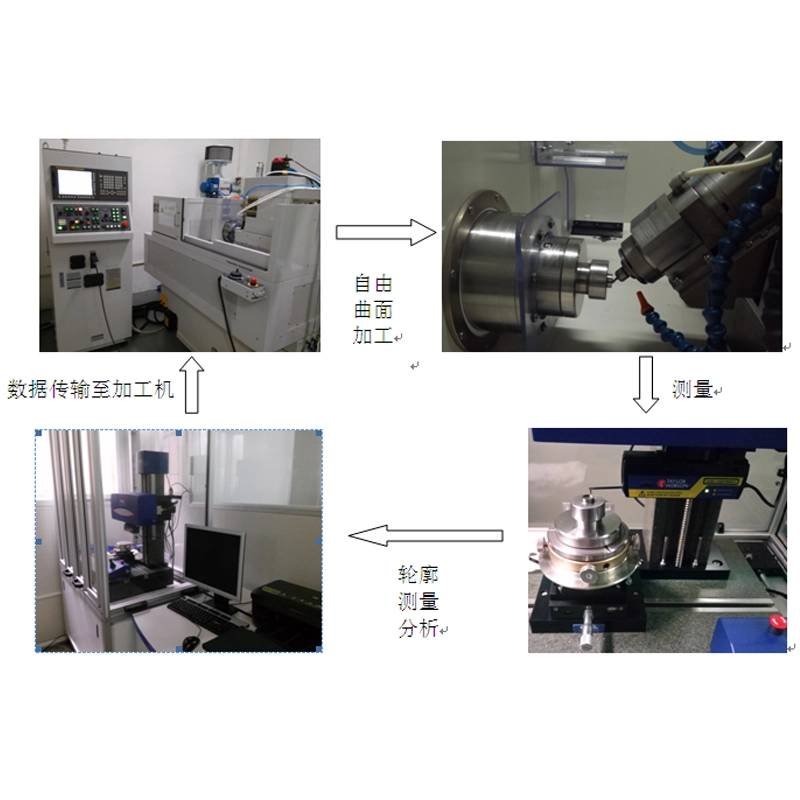

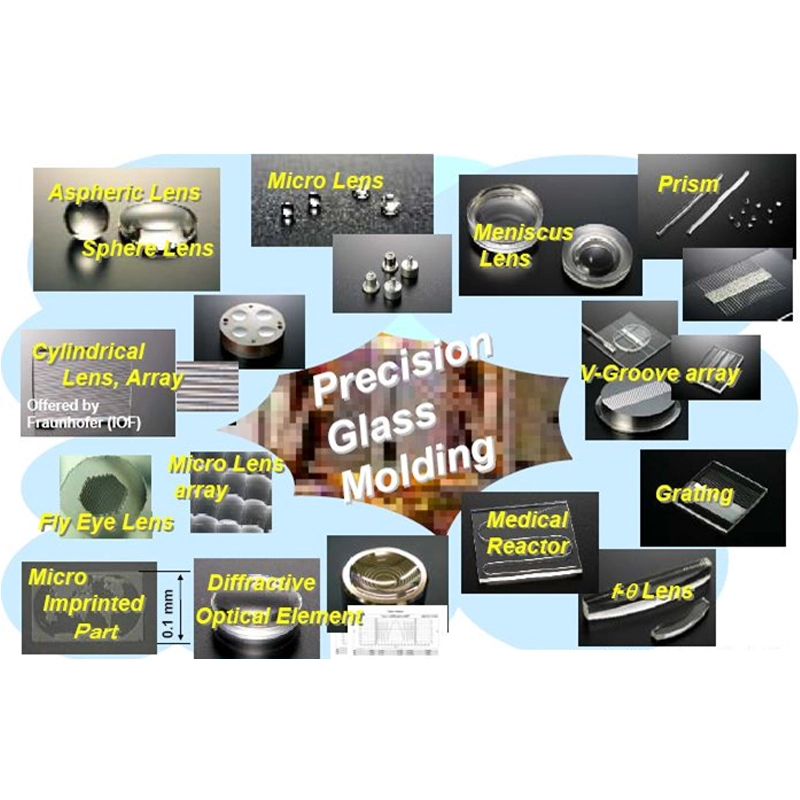

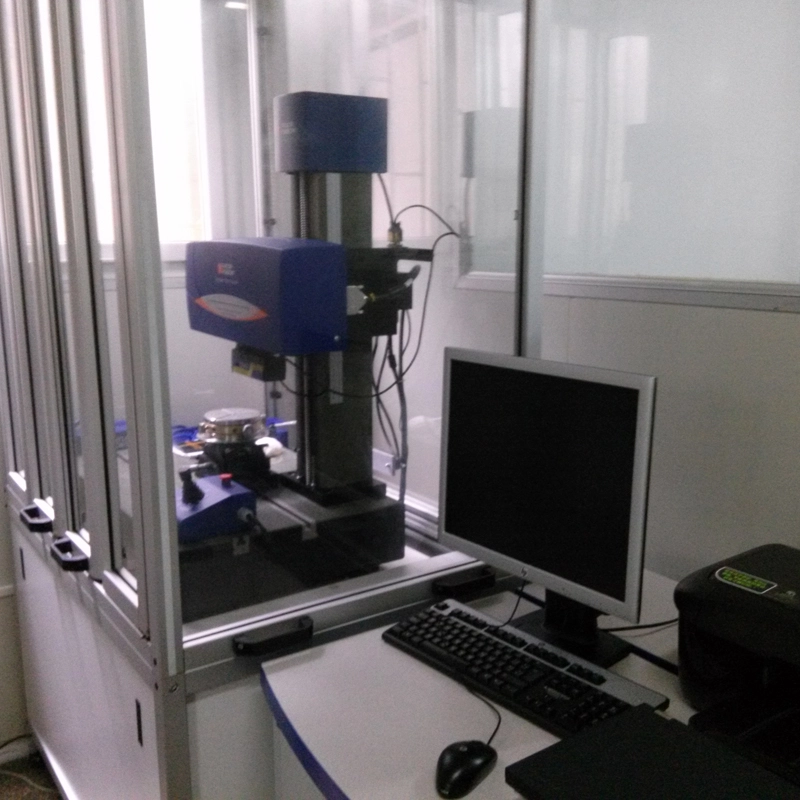

86-755-82924037Solar Valley uses a variety of manufacturing technologies to produce ultra-high-precision free-form surfaces of various materials including metal, glass, quartz, infrared, ultraviolet and other materials. It has ultra-high-precision 5-axis CNC grinding, single-point diamond CNC turning, and CNC grinding, CNC polishing, centering grinding and other process technologies to mass-produce high-precision free-form optical components. Product shapes include rotationally symmetric spheres, aspheric surfaces, various diffraction lenses, free-form surfaces, and various non-rotationally symmetric surfaces. Surface shape accuracy PV≤0.1μm, surface roughness ≤0.05μm, surface quality 40-20 or 20-10. Solar Valley can design and manufacture free optical surfaces according to customer requirements.

These advanced technologies allow Solar Valley to produce a wide variety of high-precision optical components tailored to specific applications. Among our product offerings, the optical concave mirror stands out for its exceptional ability to focus light with precision, making it indispensable in imaging and laser systems.

We also produce elliptical flat mirror, which is designed for applications requiring accurate beam reflection and manipulation. This mirror is crafted with stringent quality control to ensure their performance in demanding optical systems.

Additionally, our expertise extends to the manufacturing of optical dome lens, which provides durability and superior optical performance in environments requiring robust protective solutions.

Solar Valley's capabilities in high-precision free optical surface manufacturing ensure we can meet the diverse and evolving needs of our customers. For more information about our products and services, please contact us.