Call Us

86-755-82924037

Call Us

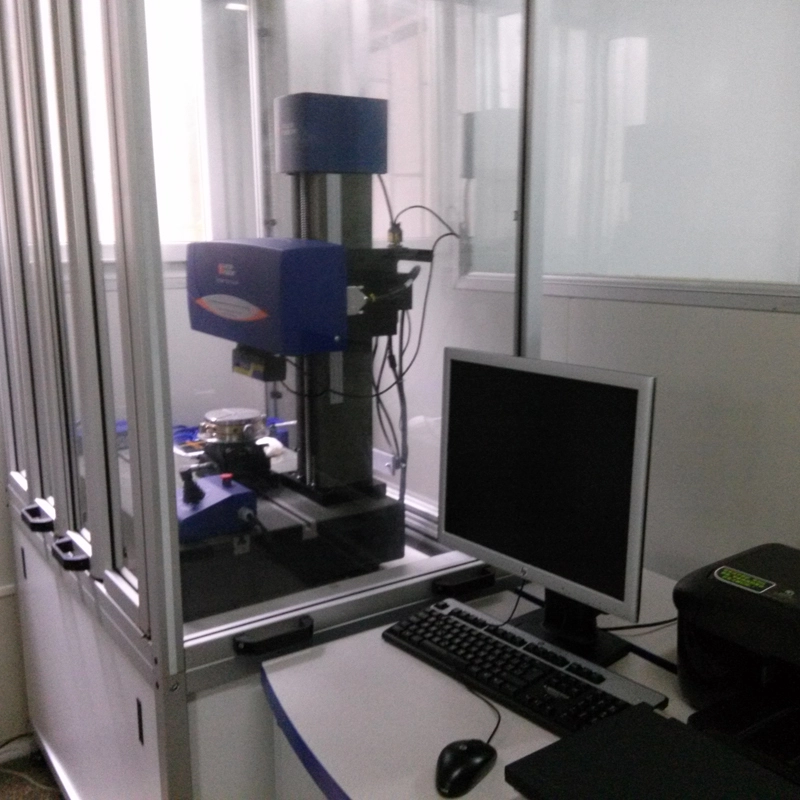

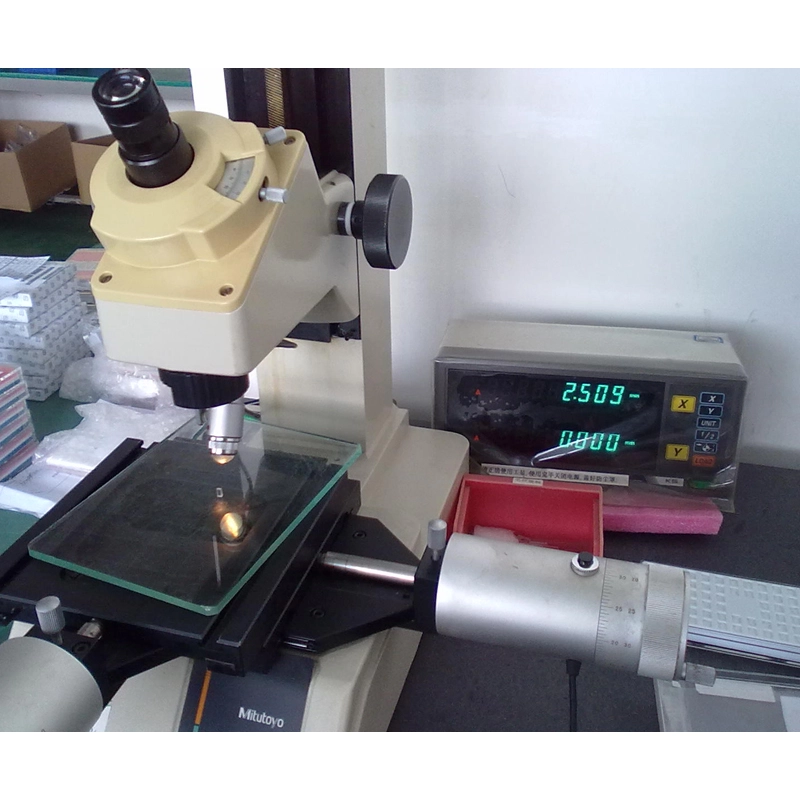

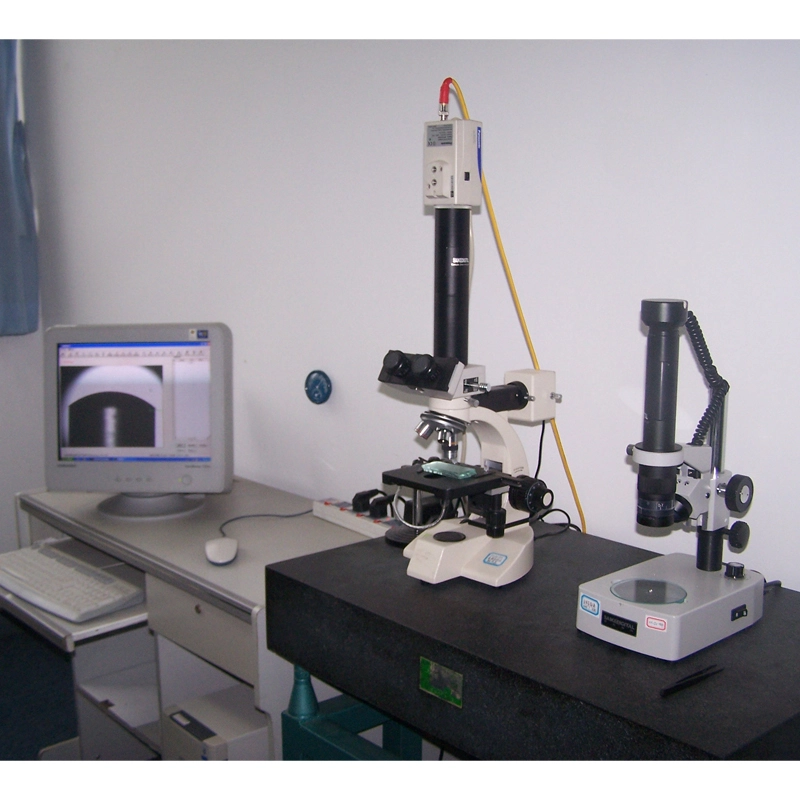

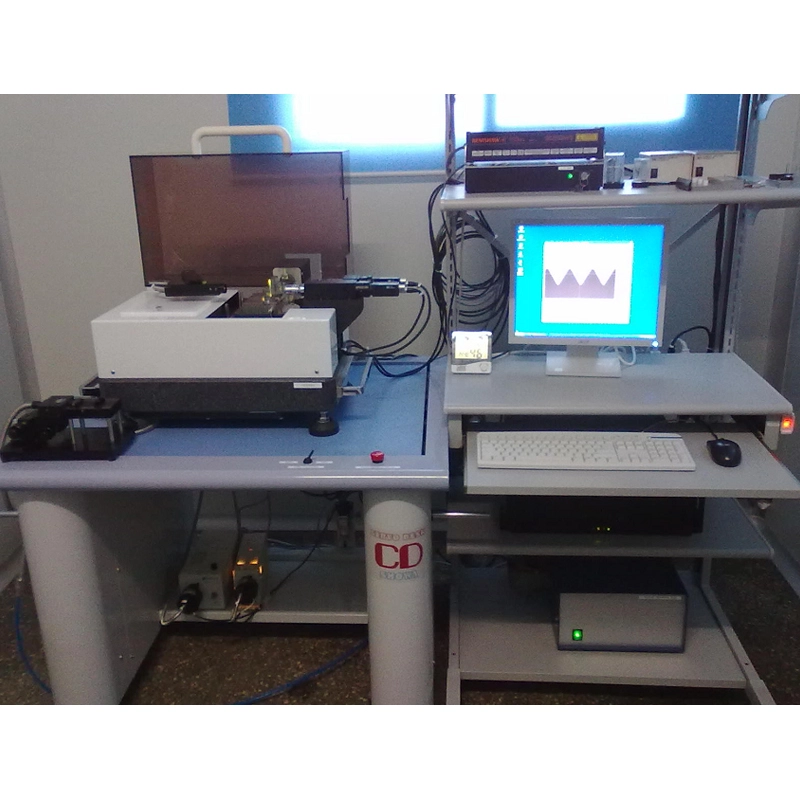

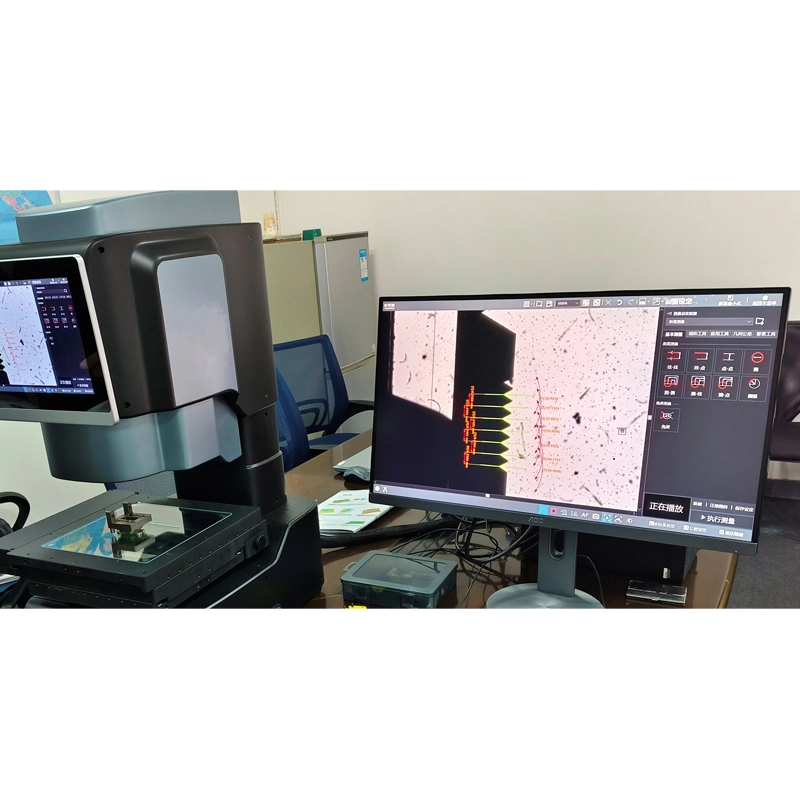

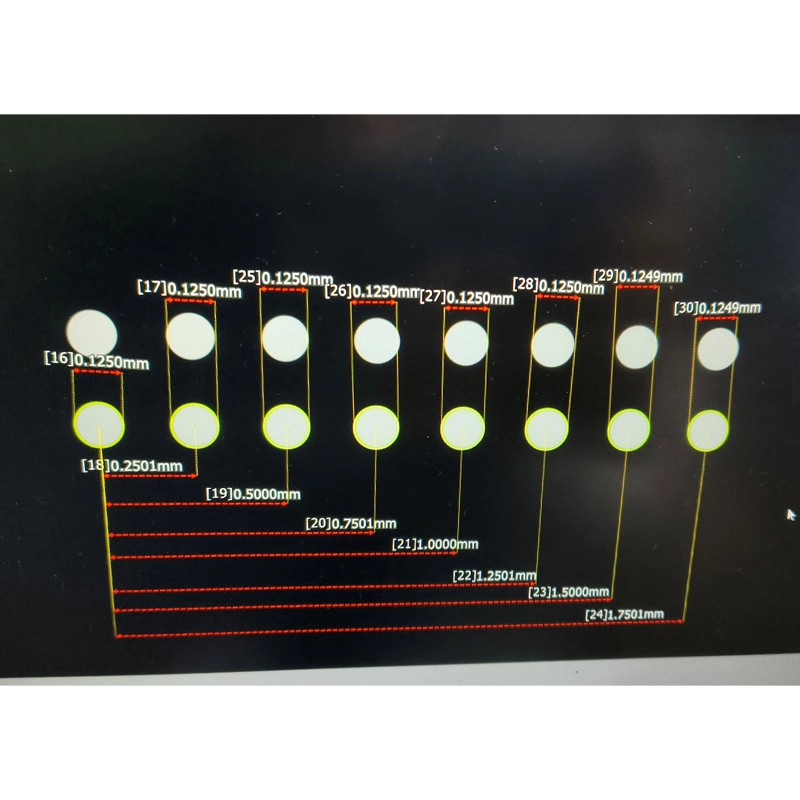

86-755-82924037Quality control is an integral part of the manufacturing of optical optical components, and Solar Valley performs ultra-high-precision manufacturing and is capable of ultra-high-precision measurements. Solar Valley carries out quality monitoring and testing at the same time as the manufacturing process, and has invested in the most advanced measurement and testing equipment in the production line to perform measurement, analysis and control during the manufacturing process.

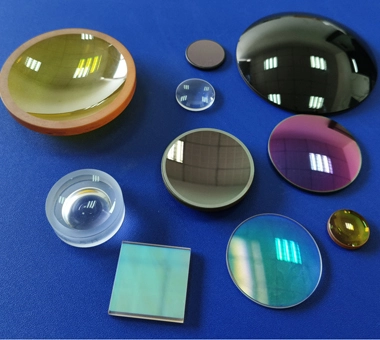

At Solar Valley, we understand that maintaining high standards of quality is essential to the success of optical component manufacturing. Our quality control processes ensure that every product, from precision optical mirrors to automotive lenses, meets rigorous performance and durability standards. We are committed to providing the highest level of quality assurance through continuous monitoring and testing during the manufacturing process.

As a trusted laser lens factory, Solar Valley produces a wide range of laser lens types, each designed to meet specific optical and performance requirements. Whether it's for laser cutting, laser marking, or optical communication, our laser lenses are manufactured with precision to ensure optimal efficiency and reliability.

In addition to laser lenses, we also provide optic prism cube, ensuring our customers receive top-tier products at affordable rates. Our robot optics are also highly sought after for use in advanced robotics, where precision and reliability are crucial for system functionality.

By investing in cutting-edge measurement and testing equipment, Solar Valley ensures that each optical component undergoes thorough inspection and analysis. This commitment to precision and quality control allows us to deliver components that perform at the highest level across various industries.

For more information about our quality control processes or to discuss your specific needs, please contact us today.