Call Us

86-755-82924037

Call Us

86-755-82924037

In the realm of manufacturing and industrial production, precision is paramount. Achieving and maintaining high-quality standards demands constant innovation and advancement in inspection methodologies. One of the profound advancements in this field has been the utilization of optical lenses. These lenses, when integrated into sophisticated inspection tools and systems, significantly elevate the accuracy and efficiency of industrial inspection processes. For instance, linear Fresnel lens is widely used in industrial lighting and inspection systems to provide uniform illumination and enhance visibility of defects.

Optical lenses find their application across a wide range of industries, from automobile manufacturing to semiconductor production. In the automotive sector, for instance, optical lenses are pivotal in inspecting components like gears and engine parts for defects that could compromise vehicle safety. Similarly, in the semiconductor industry, where the tolerance for error is minimal, optical lenses enable the inspection of microchips and circuit boards at an unprecedented level of detail, ensuring functionality and reliability. Transmitter optical subassemblies and receiver optical subassemblies, used in industrial sensors, play a crucial role in these inspection systems by ensuring precise data transmission and reception.

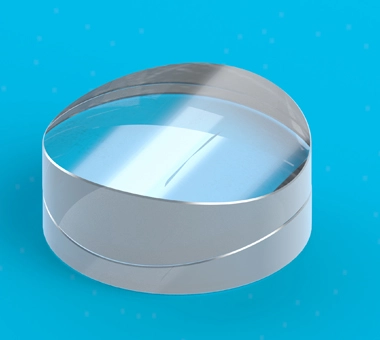

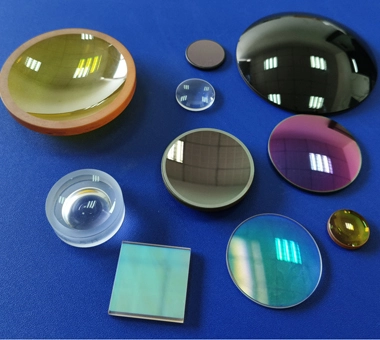

Quality control is a critical aspect of any industrial operation, where the cost of failure can be astronomical. Optical lenses come into play by providing high-resolution imaging capabilities for inspection systems. They allow for the detection of minute imperfections that might be invisible to the naked eye, such as surface flaws, dimensional inaccuracies, or structural inconsistencies. This capability enables manufacturers to ensure that every product meets stringent quality standards before it leaves the production line. Spherical glass lens and molded glass aspheric lens are commonly used in these systems to achieve the necessary precision and clarity.

The integration of optical lenses into industrial inspection systems not only improves accuracy but also enhances efficiency. Traditional inspection methods can be time-consuming and may require manual intervention, but systems equipped with advanced optical lenses can perform inspections at much higher speeds, without sacrificing precision. This improvement in efficiency can significantly reduce inspection times, leading to increased production rates and lower costs. Different laser lens types and TO can laser diodes are often employed in industrial laser systems to achieve high-speed, high-precision inspections.

A promising development in the field of industrial inspection is the integration of optical lenses with artificial intelligence (AI) technology. By combining the detailed imaging capabilities of optical lenses with the analytical power of AI, inspection systems can learn from vast amounts of data and improve their detection algorithms over time. This synergy has the potential to revolutionize industrial inspection by making it more adaptable, accurate, and efficient than ever before. Optic prism cube, which is used to split or combine light beams in industrial optical systems, elliptical flat mirror, designed to reflect light with minimal distortion, and dielectric mirror glass for sale, known for its high reflectivity and durability, are some of the components that can be integrated into these advanced systems to enhance their functionality. Each of these elements plays a crucial role in optimizing the performance and accuracy of industrial inspection and processing technologies.

In conclusion, optical lenses play a critical role in the realm of industrial inspection, offering unparalleled precision and efficiency across various sectors. As technology continues to advance, the integration of these lenses with cutting-edge solutions like AI promises to set new standards in quality control and manufacturing excellence. The significance of optical lens applications in ensuring product integrity and safety cannot be overstated, marking a key development in the ongoing evolution of industrial inspection practices. Germanium lens and ZnSe focus lens are also becoming increasingly important in specialized applications such as thermal imaging and laser systems, respectively. Additionally, optical mirrors supplier provides essential components that support the high-performance requirements of modern industrial optical systems.

Bldg. A Baolong Industrial Zone #491 Dalang South Rd. Longhua District Shenzhen China

Copyright © Shenzhen Solar Valley Scitech Development Co., Ltd. All Rights Reserved.