Call Us

86-755-82924037

Call Us

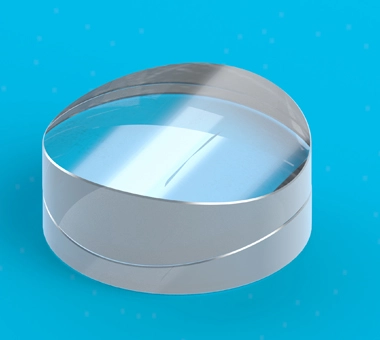

86-755-82924037Solar Valley Optical Lens, engineered for unparalleled clarity and durability, offers superior light transmission and scratch resistance. Our lenses ensure vivid, distortion-free vision, enhancing your experience with unmatched precision and comfort. Trust Solar Valley for your optical excellence.

Load cells are used for weighing or testing compression. They adopt the principle of resistance strain type, with high precision and good stability. The load cells' size and appearance have been changed to suit different types of equipment.

Tension load cell is a kind of load cell, usually S-shaped structure, which has the characteristics of high accuracy and easy installation. Part of the Tension load cell can also be used to test pressure force.

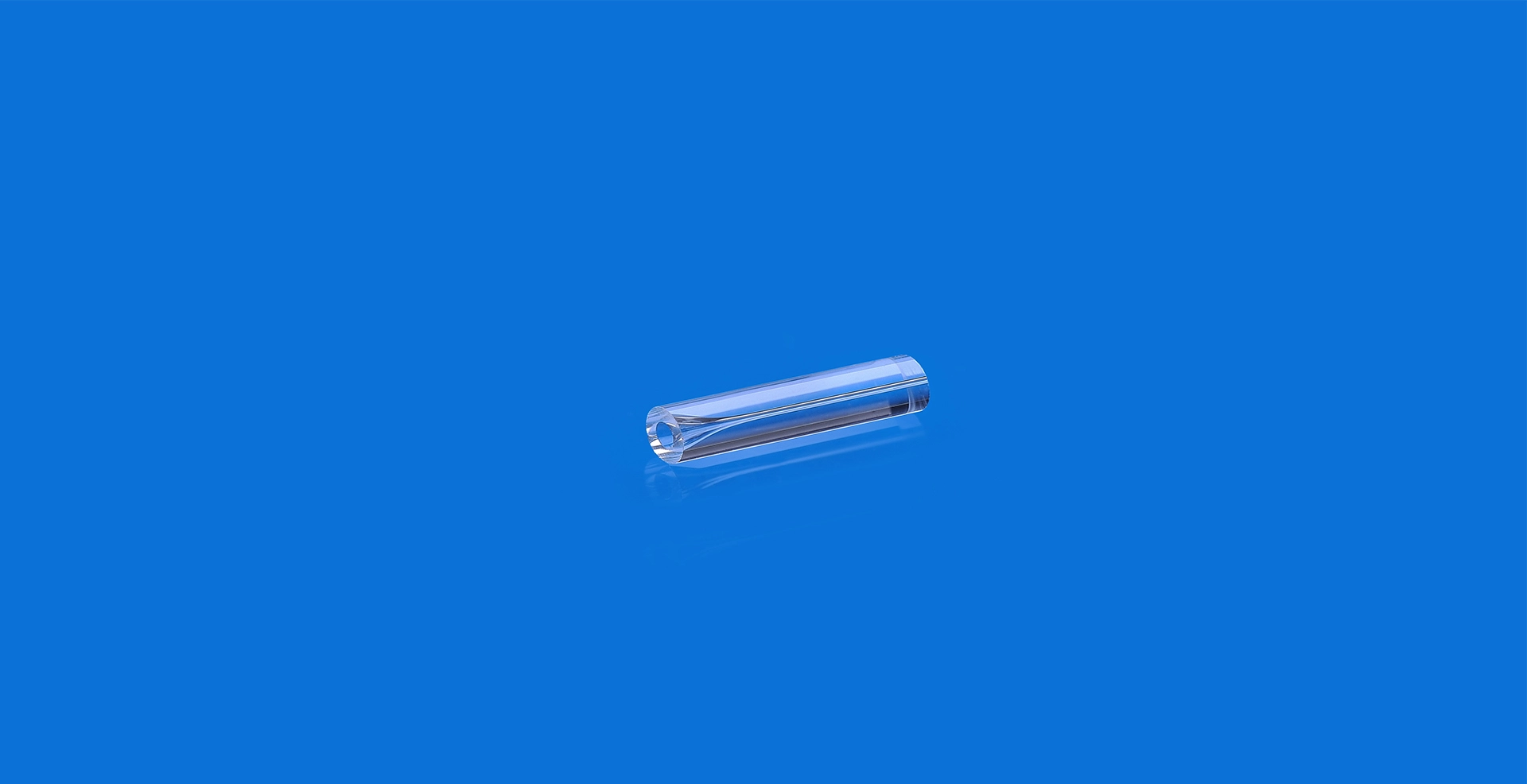

Fiber optic components, including connectors, splitters, amplifiers, and transceivers, are essential for high-speed, long-distance data transmission with minimal loss, ensuring reliable and efficient global networks.

The wire rope tension load cell is a sensor specially designed for measuring wire rope tension. Through certain calculations, the weight of the object lifted by the rope can be obtained.

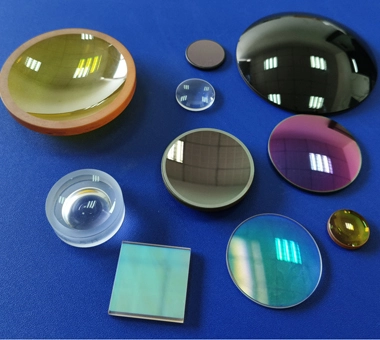

We offer a broad range of component manufacturing services, customized to your specifications. Our manufacturing capabilities enable us to meet your product material combinations for applications ranging from the ultraviolet to the infrared spectrum.

If your design includes complex optical component assemblies, such as aspherical lenses made from high-end optical glass or infrared materials for advanced applications, Solar Valley is your ideal choice. Our years of manufacturing and assembly experience can help ensure your project goals are achieved within budget.

Our lens/window manufacturing capabilities also include high-speed polishing technology and traditional classical polishing processes, allowing for prototyping in relatively small quantities for customer optical performance verification. We also offer grinding and polishing services for small batch aspherical parts.

Our advanced inspection capabilities provide comprehensive quality support for our customers, ensuring exceptional product delivery. Your parts undergo strict internal quality control. Furthermore, Solar Valley will be responsible for the optical quality of your product throughout its lifecycle at no additional cost.

Optical lenses are pivotal in various applications, including vision correction, photography, microscopy, laser processing, and astronomical telescopes, enhancing clarity and precision in diverse fields.

Automobile

Medical Inspection

Pharmaceutical Industry

Optical lenses are categorized based on their shape and function, such as convex (converging lenses), concave (diverging lenses), aspherical, and cylindrical lenses, among others.

Yes, optical lenses can be customized in terms of shape, size, material, coating, and optical properties to meet specific requirements of an application.

Choosing the right lens involves considering factors such as focal length, material, diameter, and the specific optical properties required for your application. Consulting with an optical engineer or expert can provide guidance tailored to your needs.

A spherical lens has a surface that forms part of a sphere, while an aspherical lens has a more complex surface profile that reduces optical aberrations and improves image quality.

Optical lenses should be cleaned with a soft, lint-free cloth and, if necessary, a small amount of lens cleaning solution. Avoid touching the lens surface with fingers and store lenses in a clean, dry place to prevent damage.

While optical lenses can significantly enhance and manipulate light, they are subject to physical laws and limitations, such as diffraction limits and material constraints, which can affect performance in certain applications.