Call Us

86-755-82924037

Call Us

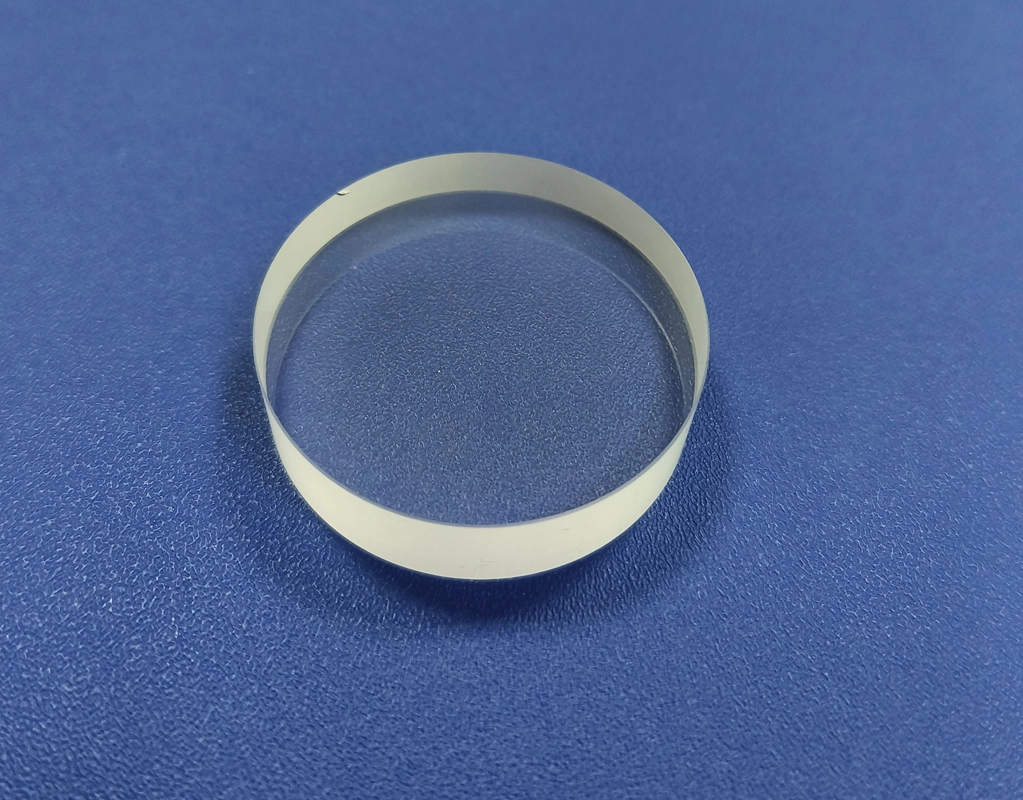

86-755-82924037Borosilicate windows excel in environments with high temperatures and challenging conditions. Thanks to their superior thermal shock resistance and stability, these windows preserve their flatness across diverse environmental scenarios.

| Borosilicate glass window product parameter table | |||

| project | Indicator requirements | ||

| 1. Material | Borosilicate glass, such as TEMPAX, PYREX, Borofloat33, etc. | ||

| 2. Diameter | OD≤300mm OD±0.025 or according to customer requirements | ||

| 3. Center thickness | T=0.1~50mm±0.01 or according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% area | ||

| 7. Coating | AR R<0.5% @λnm | ||

| 8. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9. Surface quality | 60-40, 40-20, 20-10, 10-5 | ||

One-stop customized production: Solar Valley processes various custom optical windows, circular, D-shaped, square, trapezoidal and other structural borosilicate windows according to customer requirements, and can provide different size ranges and materials. Window piece, the base material is borosilicate glass

Material: borosilicate glass, such as TEMPAX, PYREX, Borofloat33, etc.

Properties of borosilicate glass windows: strong resistance to mechanical impact and thermal shock, high surface hardness, high transmittance, suitable for use in harsh environments. It can be made very thin and is suitable for visible light use. It is usually used as a protective window for electronic sensors or detectors of the external environment. It is used to separate the environment on both sides to isolate the inside and outside of the instrument from each other, thereby protecting the internal components. Product specification description: 1. Maximum outer dimensions of borosilicate glass windows: OD ≤ φ300mm, thickness 0.1 ~ 50mm 2. Maximum outer dimensions of borosilicate glass windows: L × W ≤ 300 × 300mm 3. Borosilicate Glass windows can reach the following precision levels according to customer requirements: Ultra-high precision grade: surface shape error <0.1μm, surface roughness <0.01μm High precision grade: surface shape error <0.5μm, surface roughness <0.05μm Precision grade: surface Form error <1μm, surface roughness <0.1μm

Surface defect grade: 60-40, 40-20, 20-10, 10-5 Produced according to customer requirements.

Coating: Coating according to customer requirements.

Borosilicate glass is often considered superior to tempered glass due to its excellent thermal and chemical resistance. It withstands sudden temperature changes without cracking, making it ideal for laboratory equipment and high-heat environments. Borosilicate glass is also less likely to react with chemicals, ensuring purity in scientific applications. Conversely, tempered glass is stronger against physical impact, making it better for safety applications like windows and doors. Each type has its strengths, depending on the specific use case.