Call Us

86-755-82924037

Call Us

86-755-82924037Chalcogenide lenses use ultra-precision multi-axis free-form surface processing machine tools and are processed through ultra-high-precision fine grinding, grinding, measurement, ultra-high-precision polishing and other processes. Under precise control of the machine tool and processing environment, optical aspheric plasticity is achieved. Domain ultra-high precision processing, using ultra-high precision correction polishing technology to polish the lens surface, achieving an infrared aspheric chalcogenide lens with an optical aspheric surface shape accuracy ≤ 0.1 micron and a surface roughness Ra ≤ 0.01 micron.

| Chalcogenide lens product parameter table | |||

| project | Indicator requirements | ||

| 1. Material | There are IRG201, IRG202, IRG203, IRG204, IRG205, IRG206, IRG207, etc. | ||

| 2. Diameter | OD≤φ150mm OD±0.025 or according to customer requirements | ||

| 3. Center thickness | T±0.01 or according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% aspheric area | ||

| 7. Coating | Anti-reflection coating, reflective coating, R<0.5% @λnm | ||

| 8. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9.Surface quality | 60-40, 40-20, 20-10 | ||

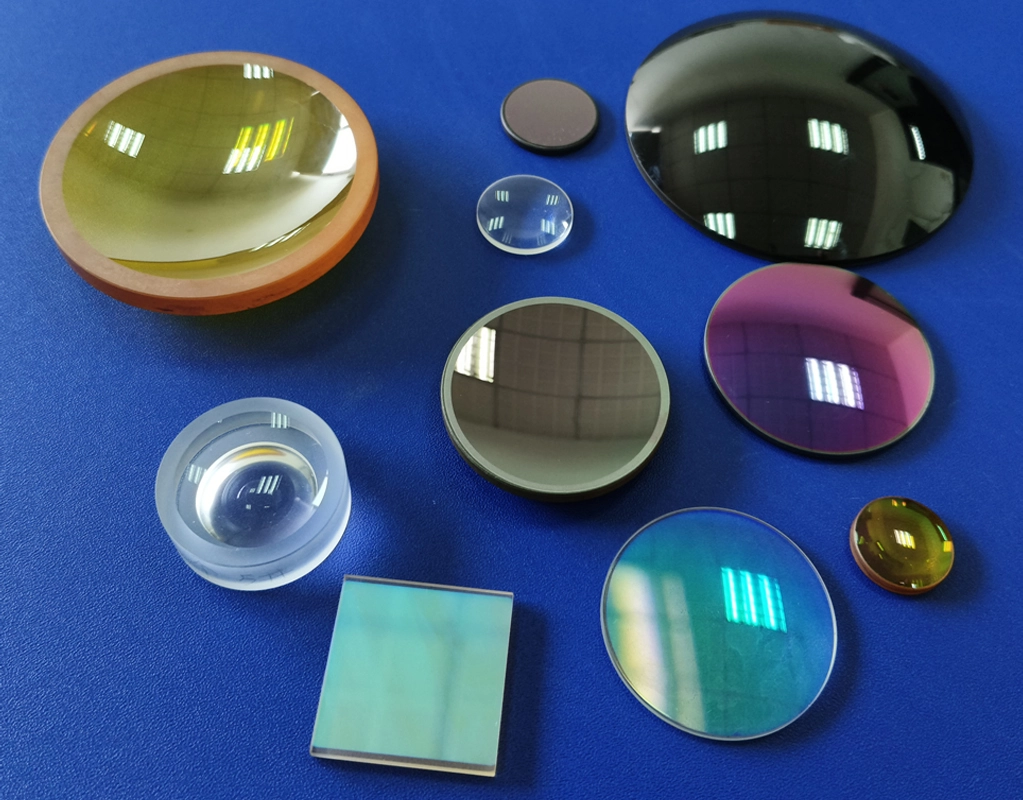

One-stop customized production: Solar Valley processes various infrared lenses, plano-convex, biconvex, and convex-concave structure aspheric chalcogenide lenses according to customer requirements. The shape of the chalcogenide lens can be circular, D-shaped, square, etc.

Chalcogenide Lens Material: The chalcogenide lens material is a special kind of glass whose composition contains a large amount of sulfur element. The main feature of chalcogenide glass is its high refractive index, generally above 1.8. Chalcogenide lens materials include IRG201, IRG202, IRG203, IRG204, IRG205, IRG206, IRG207 and other models.

Chalcogenide Lens properties: Chalcogenide lens material is a non-oxide glass material formed by introducing chalcogen elements as the main component and introducing one or more of Ge, As, Sb, Ga and other elements. It can be used as an infrared thermal imaging The lens material of the system is the "dazzling eye" of infrared temperature measurement equipment. Widely used in thermal imaging system optics for infrared windows and thermal bands (8 to 14µm), their relatively high transmittance through 3-5µm and 8-10µm makes chalcogenide lenses ideal for multispectral applications in a wide range of Used in making infrared optical components such as infrared windows, fairings and lenses.

Product indicator description:

1. Maximum dimensions of circular chalcogenide lens: OD≤φ150mm

2. Maximum dimensions of square chalcogenide lens: L×W ≤100×100mm

3. Chalcogen series lenses can reach the following accuracy levels according to customer requirements:

Ultra-high precision grade: surface error <0.1μm, surface roughness <0.01μm

High precision grade: Surface error <0.5μm, surface roughness <0.05μm Precision grade: Surface error <1μm, surface roughness <0.1μm

Similar product of gallium arsenide lens is also provided for you to explore.

Surface defect grade: 60-40, 40-20, 20-10. Produced according to customer requirements.

Coating: Coating is carried out according to customer requirements, and no coating or a variety of broadband anti-reflective coating options are available.