Call Us

86-755-82924037

Call Us

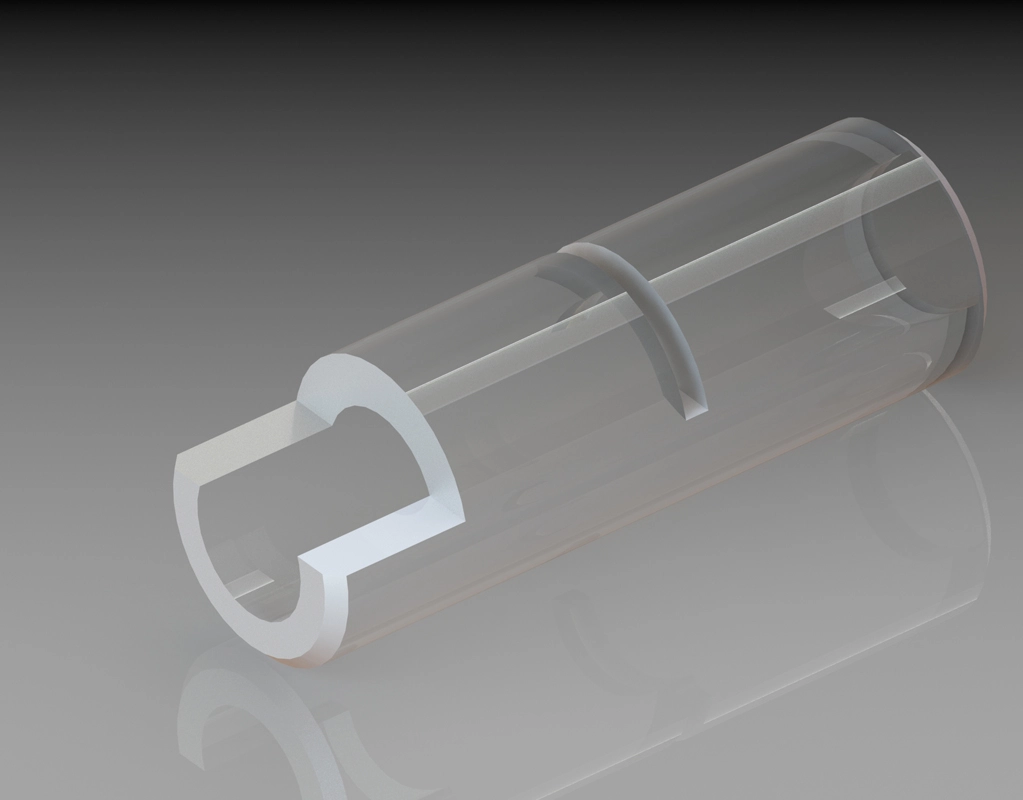

86-755-82924037Solar Valley custom glass tubes are specialized components tailored for optical communication devices, leveraging the unique properties of glass-quartz material. Compact size, exceptional precision, remarkable hardness, and superior resistance to environmental conditions make our glass tubes perfectly suited for critical roles in the assembly and stabilization of optical systems, including optical collimators, isolators, and high-power lasers.

The production process of these custom glass tubes begins with the prefabrication of a quartz mother tube. Following a meticulous cleaning process, the tube is secured above a high-temperature graphite furnace. Within this controlled environment, shielded by inert gas, the quartz undergoes a series of programmed operations—continuous pulling, drawing, and cutting—to shape the glass-quartz tubes. This method by Solar Valley glass tube manufacturer ensures the production of tubes with transparent surfaces and high dimensional accuracy on a large scale, efficiently and rapidly.

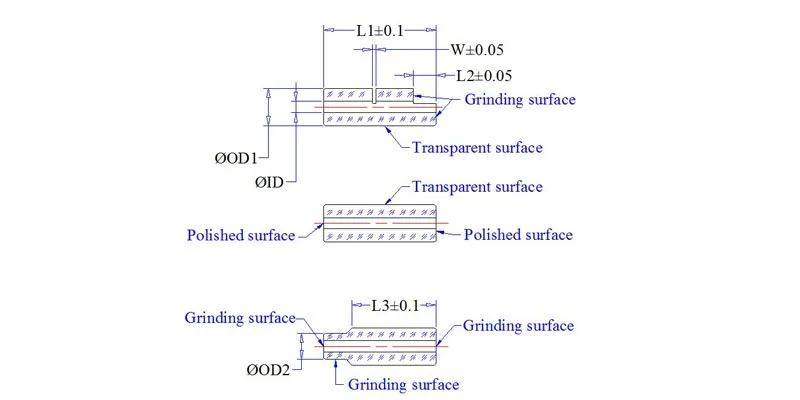

| Customized glass-quartz tube product parameter table | |||

| Project | Indicator requirements | ||

| Material properties | Material: High purity quartz, Borosilicate Glass | ||

| Dimensional accuracy | Outer diameter OD: φ0.5<OD≤φ25mm or customized according to customer requirements | ||

| Outer diameter tolerance: customized according to customer requirements | |||

| Inner diameter tolerance: customized according to customer requirements | |||

| Length L: L=0.5~100mm±0.2mm, the length can be processed according to customer requirements | |||

| surface requirements | The product has no cracks, both end surfaces are ground surfaces, and the cylindrical surface is transparent. | ||

As a premier glass tube manufacturer, we specialize in providing custom glass tubes tailored to meet the specific needs of various industrial and scientific applications. Solar Valley offers customization options including size, shape, thickness, and material. These options ensure our glass tubes is perfectly suited to the unique requirements of our B2B clients.

High purity quartz, PYREX glass, Tempax glass, Borofloat33 glass can be used, with high strength, high wear resistance and high light transmittance.

The glass-quartz tube is melted and drawn at high temperature. The surface is transparent, which eliminates surface micro-cracks and local surface hidden cracks in the optical fiber positioning holes. The glass-quartz tube has high strength and is not easy to crack and break when dispensing glue to fix the optical fiber. , high dispensing pass rate.

The hydroelectric composite wire drawing production process does not use any chemical solvents, and the material and production process do not contain or involve controlled substances required by the EU RoHS directive and Reach regulations.

Through the closed-loop control of the CNC host, feeding mechanism, traction mechanism, and laser rangefinder, glass-quartz tubes with the required diameter and inner diameter can be accurately drawn. The precision consistency is very high and the production stability is excellent.

Using a high-precision grinder to precisely grind the glass-quartz tube plane, various structures can be customized to meet the requirements for connecting and fixing optical devices.