Call Us

86-755-82924037

Call Us

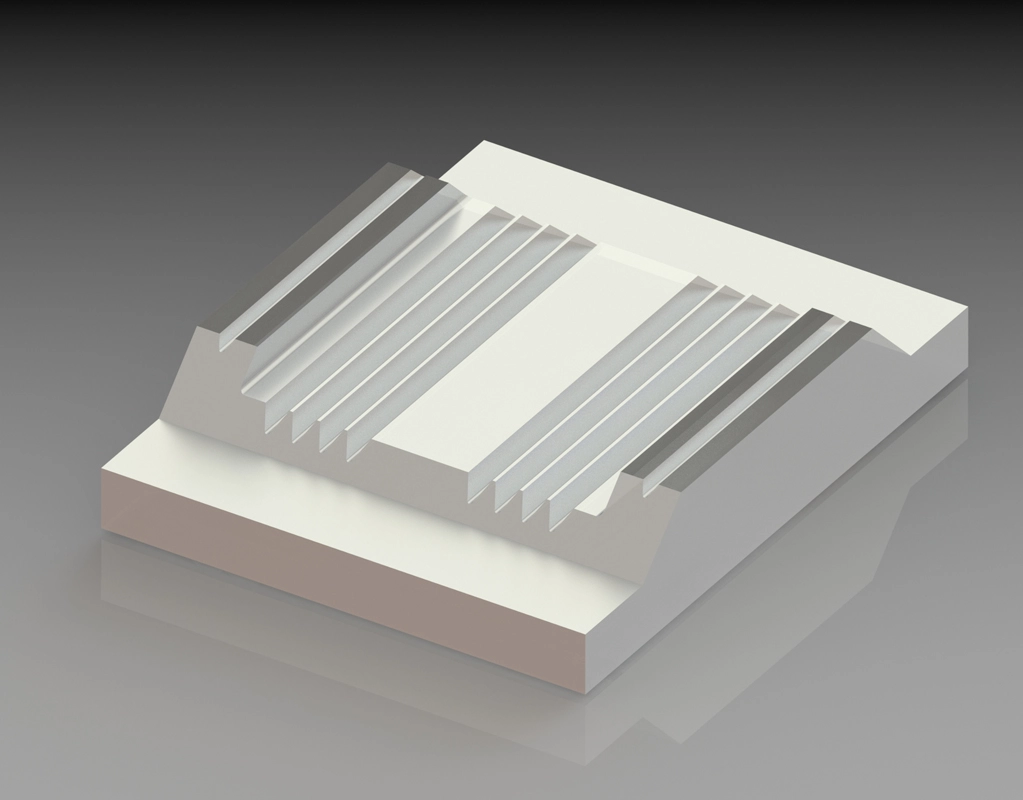

86-755-82924037Customized V-Grooves cater to specific requirements in optical fiber alignment, offering tailored solutions for precision and performance. Crafted from high-quality materials like quartz or borosilicate glass, these V-Grooves are produced using advanced, ultra-high-precision technology to ensure exact fiber positioning. Their design is meticulously customized to match the thermal expansion coefficients of specific optical fibers, guaranteeing stress-free packaging, enhanced reliability, and zero fiber displacement at elevated temperatures. Ideal for a wide range of optical devices including FAU, AWG, VOA, PLC, FTTH, and DWDM, customized V-Grooves provide a perfect fit for specialized applications, pushing the boundaries of optical communication technologies.

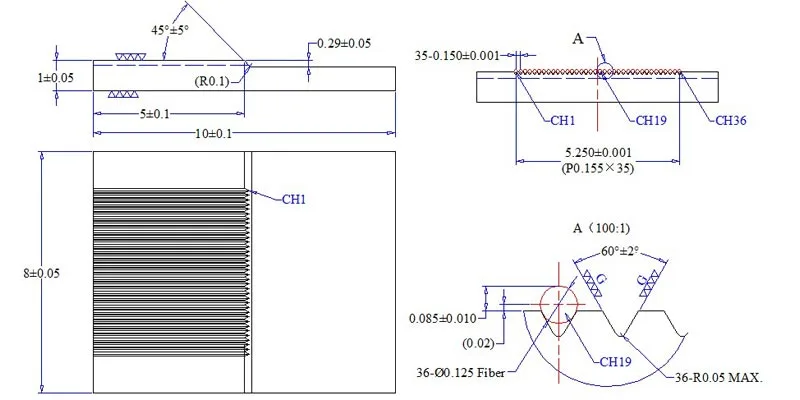

| Customized_v-grooves product parameter table | |||

| Project | Indicator requirements | ||

| Material properties | Material: high purity quartz, Borosilicate Glass, Ceramic, Carbide | ||

| Dimensional properties | Number of channels: according to customer requirements | ||

| Fiber diameter in V groove: Φ50μm, Φ80μm, Φ125μm, Φ250μm, Φ500μm | |||

| V-groove spacing P: 0.127, 0.250, 0.500, 0.750±0.0005mm, or according to customer requirements | |||

| V groove depth F: 0.03±0.01mm | |||

| V groove angle A: 60°±2°, 90°±2°, or according to customer requirements | |||

| V-groove length L: 10 or 12±0.1mm, or as per customer requirements | |||

| V-groove width W: W±0.05mm, or according to customer requirements | |||

| V groove thickness H: 0.3, 0.4, 0.5, 0.7, 1, 1.5, 2±0.05mm or according to customer requirements | |||

| Other sizes: See the standard V-groove diagram for details, or according to customer requirements | |||

| Matching cover | See the standard V-groove diagram for details, or according to customer requirements | ||

| Surface requirements | The product has no cracks, the V groove surface Ra0.2μm, the steps and sides Ra0.8μm, and other surfaces are transparent. | ||

| The matching cover sheet can be Solar Valley standard cover sheet or produced according to customer requirements. | |||

Material: High-purity quartz, PYREX glass, Tempax glass, Borofloat33 glass can be used, with high strength, high wear resistance and high light transmittance.

Quality Property: High-precision fiber core positioning size; low insertion loss and high reliability; Ultra-high-precision CNC micro-grinding is used to process the V-groove. The fiber core tolerance is ≤±0.5μm, with high precision and consistency and stable quality.

Fiber Diameter: The number of channels can be produced according to customer requirements. The diameter of the optical fiber placed in the V groove can be 50μm, 80μm, 125μm, 250μm or the fiber diameter specified by the customer.

Application:

AWG (Arrayed Waveguide Grating)

VOA (Variable Optical Attenuator)

PLC (Planar Lightwave Chip)

FTTH (Fiber to the Home)

Collimated fiber arrays and micro-optics

VCSEL and array laser chips

DWDM (Dense Wavelength Division Multiplexer)

Active/passive array fiber optic devices