Call Us

86-755-82924037

Call Us

86-755-82924037Cylindrical lens can be spherical or aspherical cylindrical lens, can be divided into flat convex cylindrical lens, flat concave cylindrical lens, double convex cylindrical lens, meniscus cylindrical mirror, fast and slow axis cylindrical lens. Cylindrical lenses are used to focus, expand, or converge light into a single dimension. Tianyanggu uses ultra-precision free-form surface CNC machining machine, the machine accuracy is less than 0.05 microns, the use of diamond grinding tools, under the condition of precise control of the machine tool and the processing environment, to achieve ultra-precision optical surface plastic field grinding, directly grinding high-precision spherical or aspherical cylindrical lenses that meet the optical quality requirements. Using ultra-high precision correction polishing technology, the surface of cylindrical lens can be polished to achieve the precision polishing of optical surface accuracy ≤0.1 micron, surface roughness Ra≤0.01 micron.

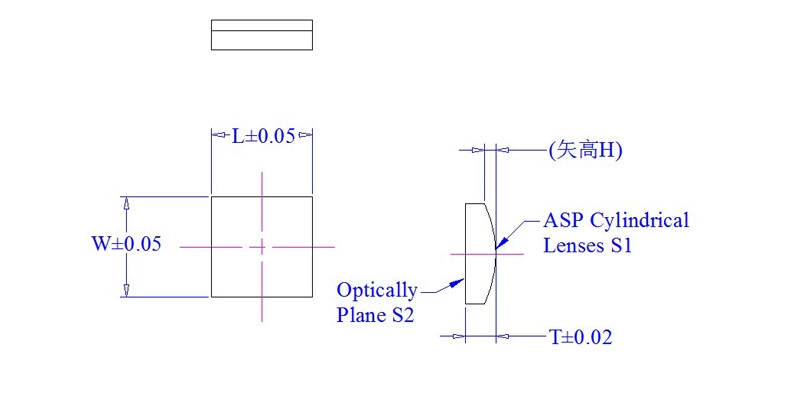

| Cylindrical Lenses product parameter table | ||

| Project | Indicator requirements | |

| 1. Material | Optical glass, optical quartz | |

| 2. Overall dimensions | Round OD≤300mm, Square L×W≤210×210mm | |

| 3. Center Thickness | T±0.02 or according to customer requirements | |

| 4. Effective focal length | according to customers needs | |

| 5. Working distance | according to customers needs | |

| 6. Design wavelength | 430~633nm, 630~780nm, 1550~1620nm | |

| 8. Coating | AR anti-reflection coating R < 0.5%@λnm according to customers needs | |

| 9. eccentricity | according to customers needs | |

| 10. Effective aperture | ED>95% aspherical area | |

| 11. Surface Shape | Ultra-high precision Rt≤0.1μm, high-precision Rt≤0.5μm, precision Rt≤1μm | |

| 12. Surface quality | 60-40, 40-20, 20-10, 10-5 | |

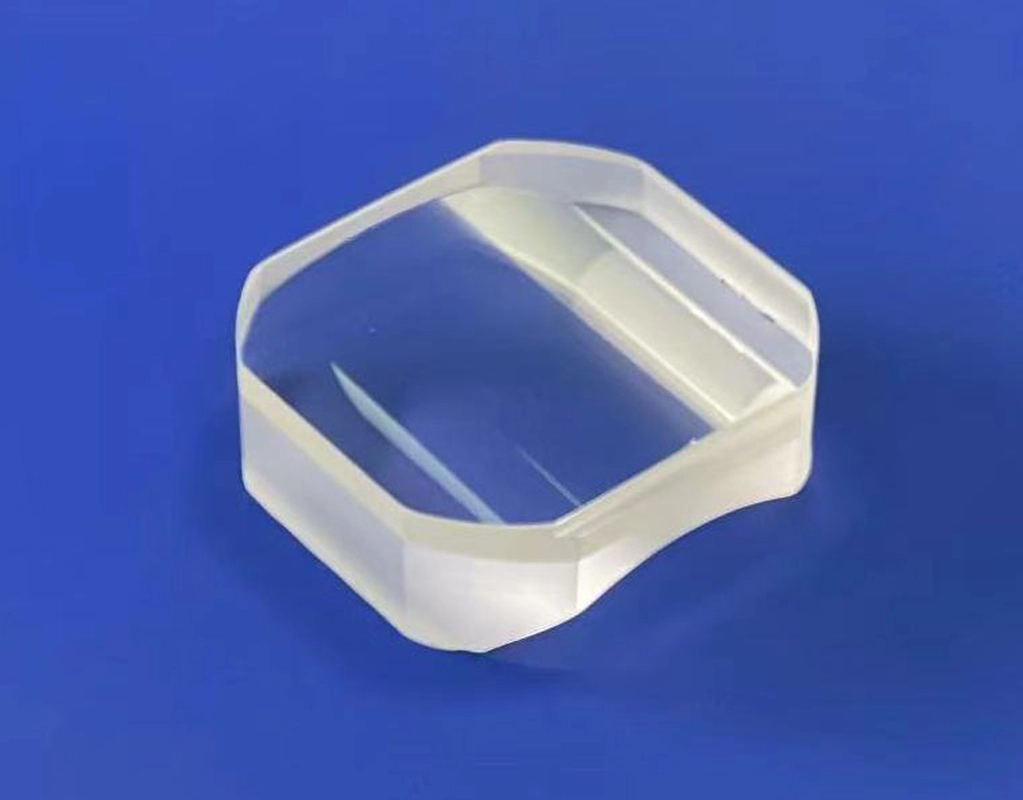

One-stop customized production: Solar Valley processes a variety of flat convex, double convex, convex and concave structure cylindrical lenses according to customer requirements. The shape of the lens can be circular, D-type, square and other shapes, the cylinder can be spherical or aspherical.

Material: The use of optical quartz, optical glass and other materials.

Cylindrical lens performance: Change the size of the imaging according to customer design requirements, such as turning the spot into a line spot, changing the height of the imaging without affecting the width. It can be used in linear detector lighting, barcode scanning, holographic lighting, optical information processing, computer, laser emission. Cylindrical lens can converge or diverge the beam on a single axis, and has a wide range of applications in optical metrology, laser scanning, spectroscopy, laser diode output beam shaping, optical film illumination microscopy and other industries and fields. Optical cylindrical lenses are widely used in intense laser systems and synchrotron radiation beams. At the same time, the requirements for cylindrical lens parts are becoming higher and higher, especially in some high-precision test instruments and devices.

Product indicators:

1. The maximum external dimension of circular cylindrical lens: OD≤φ300mm

2. The maximum external dimension of square cylindrical lens: L×W≤210×210mm

3. Aspherical cylindrical lens can reach the following accuracy levels according to customer requirements:

Ultra-high precision: surface shape error < 0.1μm, surface roughness < 0.01μm

High precision grade: Surface error < 0.5μm, surface roughness < 0.05μm Precision grade: Surface error < 1μm, surface roughness < 0.1μ

Surface defect grade: 60-40, 40-20, 20-10, 10-5 According to customer requirements.

Coating: Coating according to customer requirements.