Call Us

86-755-82924037

Call Us

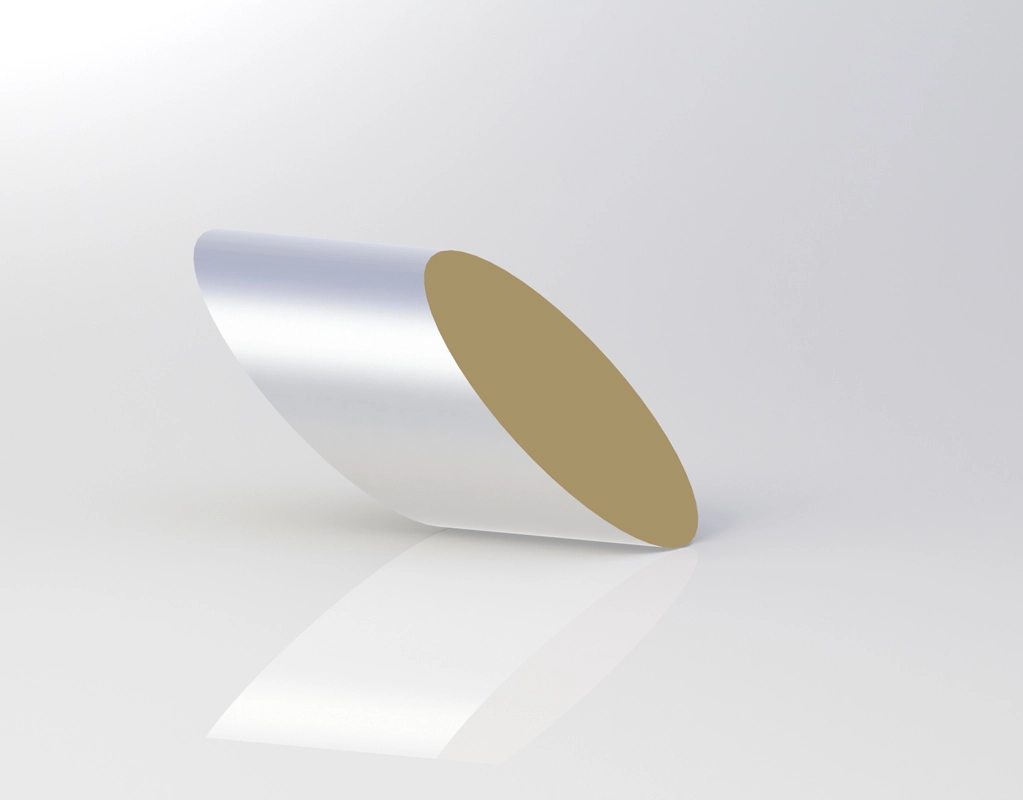

86-755-82924037Elliptic mirror is a flat mirror, the cylinder is processed by 45°, the section is oval, the outer cylinder and the mirror are 45° Angle. When the elliptic mirror is installed in the optical path at 45°, the optical aperture of the lens is exactly circular. Elliptical mirror using CNC precision machining machine, milling, fine grinding, grinding, polishing process processing, can achieve high precision mirror, under the condition of precise control of the machine tool and processing environment, paraboloid plastic field ultra-high precision machining, directly machining oval mirror in line with the optical quality requirements, surface shape accuracy ≤0.1 micron. Surface roughness Ra≤0.01 micron.

| Elliptical Mirrors product parameter table | ||

| project | Indicator requirements | |

| 1. Material | The substrate uses glass, quartz, various metals and other materials, according to customer requirements. | |

| 2. Dimension | Round OD≤150mm Square W x L≤100 x 100mm | |

| 3. Center Thickness | T≤50mm according to customer requirements | |

| 4. Effective focal length | according to customers needs | |

| 5. Working Distance | according to customers needs | |

| 6. Design Wavelength | Visible to near infrared region | |

| 7. Coating | Gold plated film, silver film, aluminum film, or ultraviolet enhanced aluminum film | |

| 8. Parallelism | 3′ | |

| 9. Effective aperture | ED > 90% aspherical area | |

| 10. Surface shape | Ultra-high precision Rt≤0.1μm, high-precision Rt≤0.5μm, precision Rt≤1μm | |

| 11. Surface quality | 60-40, 40-20, 20-10 | |

One-stop customized production: Solar Valley processes a variety of round, D, square, trapezoidal structure oval mirror according to customer requirements.

Material: The base material uses optical glass, quartz, aluminum alloy, various metals and other materials, according to customer requirements.

Elliptical mirror performance: Elliptical mirror is divided into metal coating mirror and dielectric coating mirror. Wide-band dielectric films have high reflectance, metal-film reflectors have wide reflective bands, and elliptical mirrors are typically used for 45° circular cross sections requiring a given size. Tianyang Valley elliptic mirror series by standard optical glass, quartz, aluminum alloy and other substrates processing, visible light application of 99% reflectivity. Usually elliptic mirrors are used as secondary mirrors in Newtonian telescopes or installed in tubes where maximum aperture is required, such as in periscopes.

Product indicators:

1. The maximum external dimension of circular elliptic mirror: OD≤φ150mm

2. Maximum outline size of square oval mirror: ≤100×100mm

3. The elliptic mirror can reach the following accuracy levels according to customer requirements:

Ultra-high precision: surface shape error < 0.1μm, surface roughness < 0.01μm

High precision grade: Surface error < 0.5μm, surface roughness < 0.05μm Precision grade: Surface error < 1μm, surface roughness < 0.1μm

Surface defect grade: 60-40, 40-20, 20-10 according to customer requirements.

Coating: Gold, silver, aluminum, or UV-enhanced aluminum, with protected Al coating and UV-enhanced Al coating in various sizes, according to customer requirements.