Call Us

86-755-82924037

Call Us

86-755-82924037The gallium arsenide lens (GaAs lens) uses a single-point diamond ultra-precision multi-axis free-form surface processing machine tool, and is processed through ultra-high-precision single-point turning, grinding, measuring, ultra-high-precision polishing and other processes. Under precise control of the machine tool and processing environment, To achieve ultra-high precision processing in the plastic domain of optical aspheric surfaces, ultra-high precision correction polishing technology is used to polish the lens surface to achieve an infrared aspheric lens with an optical aspheric surface shape accuracy ≤ 0.1 micron and a surface roughness Ra ≤ 0.01 micron.

| Gallium Arsenide Lenses product parameter table | |||

| Project | Indicator requirements | ||

| 1. Material | Gallium Arsenide materials | ||

| 2. Diameter | OD<100mm OD±0.025 or according to customer requirements | ||

| 3. Center thickness | T±0.01 or according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% aspheric area | ||

| 7. Coating | AR coating R<0.5% @λnm | ||

| 8. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9. Surface quality | 60-40, 40-20, 20-10 | ||

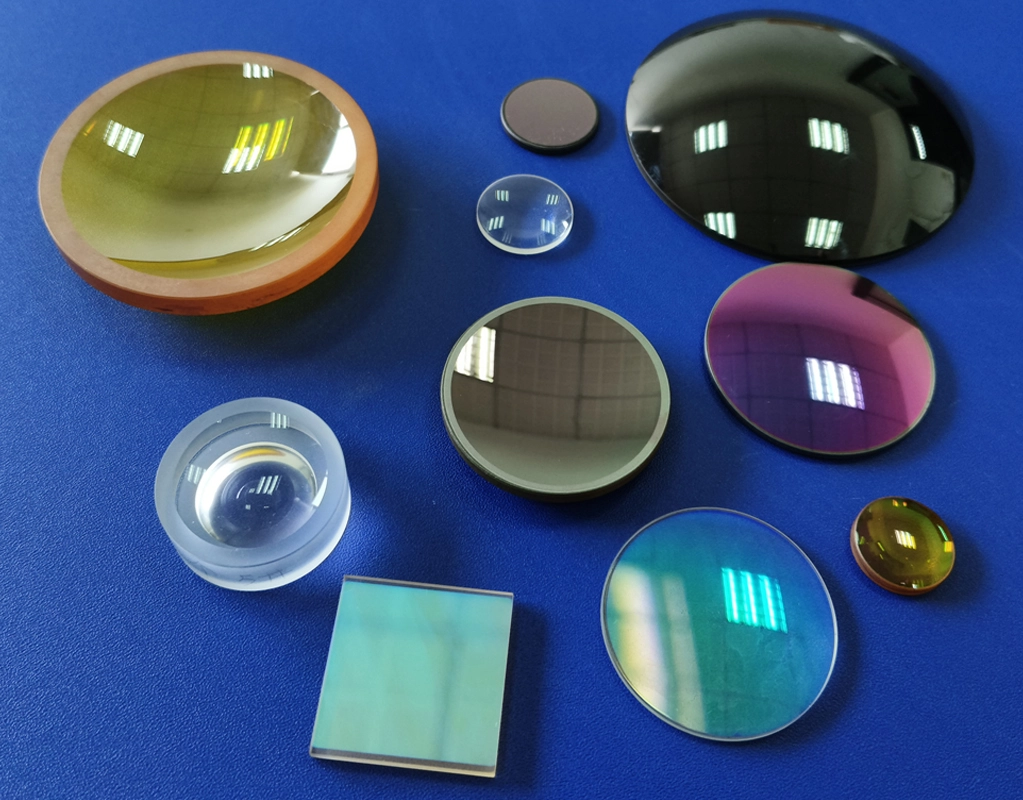

ne-stop customized production: Solar Valley processes various infrared lenses, plano-convex, biconvex, and convex-concave structure gallium arsenide lenses according to customer requirements. The shape of the gallium arsenide lens can be circular, D-shaped, square, etc.

Material: Gallium arsenide is a semi-insulator. It can replace zinc sulfide to make lenses and tail mirrors in high-power continuous CO2 laser systems. Gallium arsenide can be particularly useful in applications where toughness and durability are important.

Lens properties: Gallium arsenide lenses have good chemical stability, high hardness, and are resistant to harsh application environments. When the on-site environment is poor and the optical lens or window needs to be wiped repeatedly, gallium arsenide (GaAs) is often used An alternative to zinc selenide (ZnSe) as a material for infrared lenses or windows

Product indicator description:

1. Maximum dimensions of circular gallium arsenide lens: OD<φ100mm

2. Maximum dimensions of square gallium arsenide lens: L×W<65×65mm

3. Gallium arsenide lenses can reach the following accuracy levels according to customer requirements:

Ultra-high precision grade: surface error <0.1μm, surface roughness <0.01μm

High precision grade: Surface error <0.5μm, surface roughness <0.05μm Precision grade: Surface error <1μm, surface roughness <0.1μm

Surface defect grade: 60-40, 40-20, 20-10. Produced according to customer requirements.

Coating: Coating is carried out according to customer requirements, and no coating or a variety of broadband anti-reflective coating options are available.

Gallium Arsenide (GaAs) is a semi-insulator that can replace zinc sulfide in lens or mirror forms for large power continuous CO2 laser systems due to its toughness and durability. The gallium arsenide lens (GaAs lens) is particularly advantageous in applications where the optical element surface may be impacted by particles of dust or steel, thanks to its hardness and strength. Originally intended for semiconductor applications, GaAs requires careful screening of materials to ensure high-quality optical components. The GaAs focus lens is subject to the restriction of crystal growth technology, limiting its diameter generally to below 10 cm. Despite being hygroscopic, GaAs lenses are suitable for both laboratory and field applications due to their stable chemical properties, except when in contact with strong acids. Solar Valley provides stable quality GaAs components to fulfill infrared application designs, offering both uncoated and coated GaAs substrates. Whether you need a GaAs lens or a GaAs focus lens, Solar Valley is a reliable choice for custom manufacturing needs.

| Types | Products |

| A. Optical Lenses & Components | Germanium Lens Price |

| Cemented Achromatic Doublet | |

| Magnesium Fluoride Lens | |

| Laser Lens Factory | |

| Optical Glass Prism Cube | |

| Dichroic Mirror Price | |

| UV Dome | |

| Corner Cube China | |

| B. Optical Subassemblies (TOSA/ROSA/BOSA) | Transmitter Optical Sub Assembly (TOSA) |

| Receiver Optical Sub Assembly (ROSA) | |

| Bidirectional Optical Subassembly (BOSA) | |

| C. Quartz/Glass Products | Quartz Rods for Sale |

| Quartz Capillary Tube | |

| Quartz Capillaries | |

| Thin Wall Glass Tubing |