Call Us

86-755-82924037

Call Us

86-755-82924037Infrared aspherical lens uses a single point diamond ultra-precision multi-axis free-form surface machining machine, going through ultra-precision single point turning, grinding, measurement, ultra-precision polishing and other processes. Under the condition of precise control of the machine tool and processing environment, the optical aspherical plastic domain ultra-precision machining is achieved. The ultra-high precision correction polishing technology is used to polish the lens surface, and the optical aspherical surface shape accuracy is less than 0.1 micron, and the surface roughness Ra is less than 0.01 micron.

| IR Asphere Lenses product parameter table | |||

| Project | Indicator requirements | ||

| 1.Material | Monocrystalline germanium, monocrystalline silicon, zinc selenide, zinc sulfide, gallium selenide and other infrared materials. | ||

| 2. Diameter | OD±0.025 or according to customers needs | ||

| 3. Center thickness | CT±0.01 or according to customers needs | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% aspheric area | ||

| 7.Coating | AR R<0.5% @λnm | ||

| 8. Surface shape | Ultra high precision Rt≤0.1μm,High precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9.Surface quality | 60-40, 40-20, 20-10 | ||

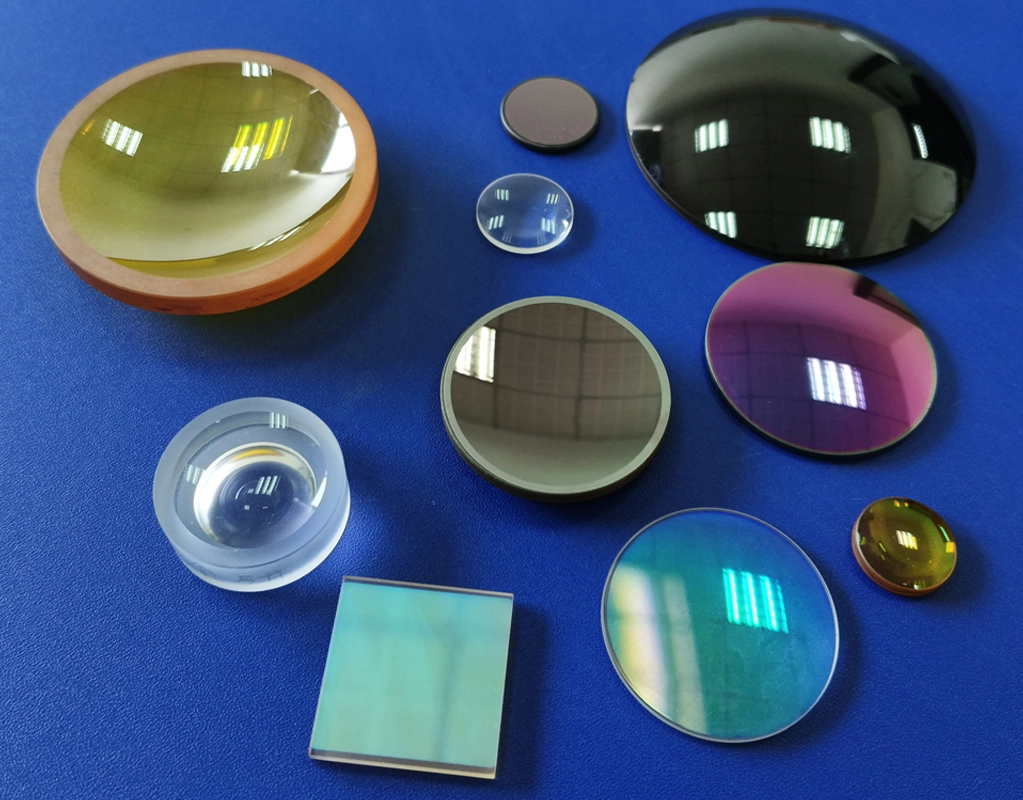

One-stop customized production: Solar Valley processes various plano-convex, biconvex, and convex-concave structure spherical lenses according to customer requirements. The lens shape can be circular, D-shaped, square, trapezoidal, etc. For more custom aspherical lenses, contact Solar Valley.

Material: Monocrystalline germanium, monocrystalline silicon, zinc selenide, zinc sulfide, gallium selenide and other infrared materials.

Lens properties: uniform light spot, clear projection, complete specifications, aerospace quality.It is used in night vision goggles, medical endoscope, laser processing, infrared thermal imager, temperature recorder, infrared fundus camera, satellite infrared telescope and so on

Product indicator description:

1. Maximum dimensions of circular spherical lens: OD≤φ150mm

2. Maximum dimensions of square spherical lens: ≤210×210mm

3. IR Asphere Lenses can reach the following accuracy levels according to customer requirements:

Ultra high precision grade: surface error <0.1μm, surface roughness <0.01μm

High precision grade: surface error <0.5μm, surface roughness <0.05μm

Precision grade: surface shape error <1μm, surface roughness <0.1μm

Surface defect grade: 60-40, 40-20, 20-10, 10-5. Produced according to customer requirements.

Coating: Coating according to customer requirements.