Call Us

86-755-82924037

Call Us

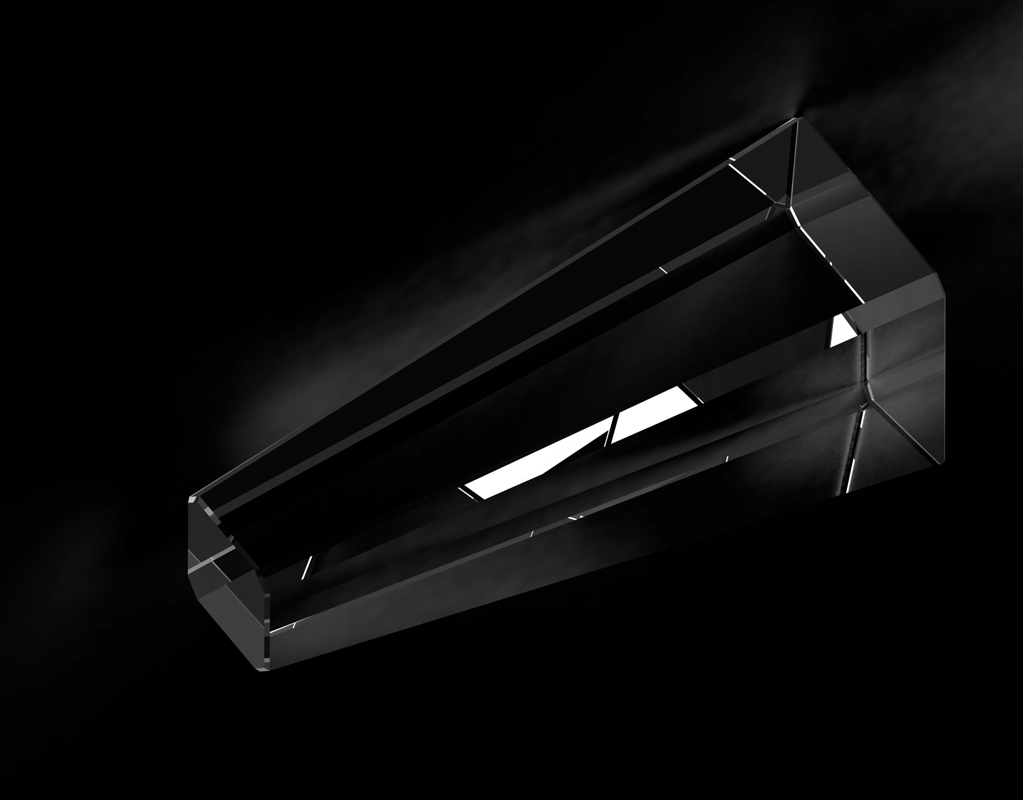

86-755-82924037The light guide cone/light guide block/light guide strip is processed by fine grinding, grinding, measurement, ultra-high precision polishing, coating and other processes. Under the condition of precise control of the machine tool and the processing environment, the ultra-high precision correction polishing technology is used to polish the window surface, and the optical guide cone/light guide block is achieved with the optical plane shape accuracy ≤0.1 micron and the surface roughness Ra≤0.01 micron. It is a key component in cosmetic laser or intense pulsed light applications.

| Light Guides product parameter table | |||

| Project | Indicator requirements | ||

| 1. Material | Sapphire, optical quartz, optical glass, light crystal light guide materials | ||

| 2. Section size | L×W ≤100×100±0.1 or according to customers needs | ||

| 3. Length/Thickness | T=0.1~50mm±0.05 or according to customers needs | ||

| 4. Effective aperture | ED>90% area | ||

| 5. Coating | Anti-reflection coating, broadband narrow band filter, high internal reflection coating | ||

| 6. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 7. Surface quality | 40-20, 20-10 | ||

One-stop customized production: Solar Valley processes a variety of custom optical windows, rectangular, rectangular, conical, trapezoidal structure of light guide cones/light guide blocks/light guide bars according to customer requirements..

Material: Provide sapphire, optical quartz, optical glass, light guide crystal and other materials of light guide cone/light guide block/light guide strip. It is a key component in beauty laser or intense pulse light applications, with excellent physical, chemical, optical properties, high temperature resistance, high hardness, is an essential optical guide cone/optical guide block/optical guide strip material with high stability optical coefficient.

Light guide cone/light guide block/light guide strip characteristics: provides over 90% transmittance between 330 and 2000nm, which makes this material an excellent choice for cosmetic laser applications, good thermal conductivity, high transmittance, higher laser damage threshold, corrosion resistance, high hardness, strong resistance to mechanical and thermal shock; Resistance of high power laser, can coating band 530-1200 nm, 640-1200 nm, 690-1200 nm, 808 nm, 755 nm, 1064 nm, can according to customer requirements for three wavelengths hybrid coating, the anti-reflection coating, broadband, narrowband filters, high reflection coating.

Product size indicator description: to figure processing custom all kinds of special-shaped light guide cones/light guide blocks/light guide bars

Maximum dimensions: L×W×T ≤100×100×50mm

According to customer requirements, the following accuracy levels can be achieved:

Ultra-high precision: surface shape error < 0.1μm, surface roughness < 0.01μm

High precision grade: Surface error < 0.5μm, surface roughness < 0.05μm Precision grade: Surface error < 1μm, surface roughness < 0.1μm

Surface defect grade: 40-20, 20-10 according to customer requirements.

Coating: Coating according to customer requirements.