Call Us

86-755-82924037

Call Us

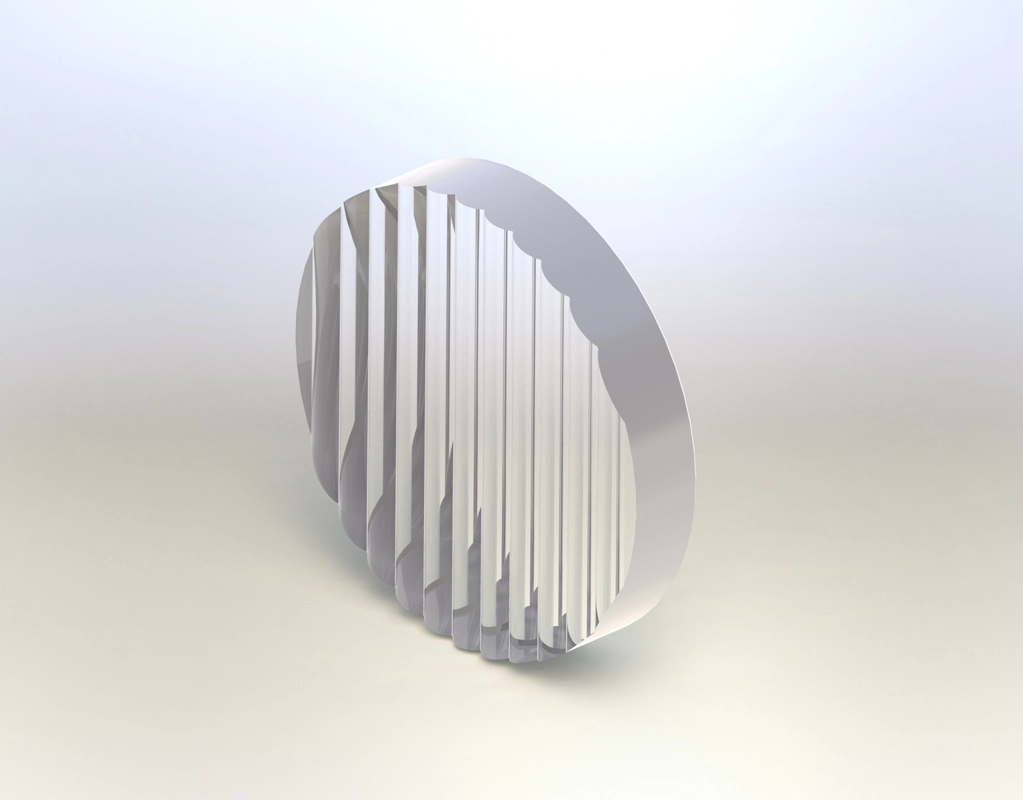

86-755-82924037One side of the line-generating Fresnel lens is an optical plane, and the other side is composed of a series of strip-shaped optical surfaces. Each optical surface has a different angle, but they all focus the light on a line to form a linear focus. Each optical surface can be regarded as an independent lens, adjusting the light into parallel linear light and emitting it. Tianyang Valley offers a variety of sector-shaped angular line-generating Fresnel lenses. Line-generating Fresnel lenses can produce uniform energy distribution along the line for laser alignment and machine vision applications. Solar Valley uses high-precision high-temperature molding machines and ultra-high-precision molds to perform high-temperature molding on glass glass materials to produce high-precision line-generated Fresnel lenses. The advantages are low production cost, high precision, and suitable for mass production.

| Line generation Fresnel lens parameter table | |||

| project | Indicator requirements | ||

| 1.Material | Use optical glass materials | ||

| 2. Overall dimensions | Round OD≤30mm, square L×W≤20×20mm | ||

| 3. Center thickness | T≤5±0.02 according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Design wavelength | according to customers needs | ||

| 7.Coating | AR anti-reflection coating R<0.5% @λnm according to customer requirements | ||

| 8. Eccentricity | according to customers needs | ||

| 9. Effective aperture | ED>90% aspheric area | ||

| 10. Surface shape | High precision Rt≤0.5μm, precision Rt≤1μm | ||

| 11.Surface quality | 60-40, 40-20 | ||

One-stop customized production: Solar Valley processes wire-generated Fresnel lenses of various sizes and structures according to customer requirements. The lens shape can be round, D-shaped, square, etc. The strip-shaped optical surface can be a spherical surface or an aspherical cylinder.

Material: Use various optical glass materials.

Line-generated Fresnel lens properties: Tianyanggu can design and manufacture according to customer requirements. Line-generated Fresnel lens sector angles can be provided in 110°, 20°, 14°, and 10°. The lenses have high precision, excellent optical performance, high temperature resistance, and are easy to install for laser alignment, machine vision applications, intense laser systems, and synchrotron radiation beam applications.Product specification description: 1. Maximum outer dimensions of line-generated Fresnel lenses: OD≤φ30m 2. Maximum outer dimensions of square line-generated Fresnel lenses: L×W≤20×20mm 3. Aspherical cylindrical lenses are available according to customer requirements Reach the following accuracy levels: High precision level: surface shape error <0.5μm, surface roughness <0.05μm Precision level: surface shape error <1μm, surface roughness <0.1μm

Surface defect level: 60-40, 40-20 Produced according to customer requirements.

Coating: Coating according to customer requirements.

Fresnel lenses are thin, flat lenses with a series of concentric rings or grooves on one side that act like a prism to focus light. They are lighter and thinner than traditional lenses for the same optical power. There are two primary types: spot and linear.

Spot Fresnel Lens

Focus: Concentrates light into a small, intense spot.

Shape: Typically circular.

Applications: Solar concentrators, magnifying glasses, projection systems, and lighting fixtures.

Linear Fresnel Lens

Focus: Creates a linear focal line.

Shape: Rectangular or cylindrical.

Applications: Solar thermal power plants, linear lighting systems, and certain types of projectors.

Visual Representation

In essence, the primary difference between spot and linear Fresnel lenses lies in the shape of the focal area they produce. This difference in focus determines their suitability for various applications.

| Types | Products |

| A. Optical Lenses & Components | Germanium Lens Price |

| Cemented Achromatic Doublet | |

| Magnesium Fluoride Lens | |

| Laser Lens Factory | |

| Optical Glass Prism Cube | |

| Dichroic Mirror Price | |

| UV Dome | |

| Corner Cube China | |

| B. Optical Subassemblies (TOSA/ROSA/BOSA) | Transmitter Optical Sub Assembly (TOSA) |

| Receiver Optical Sub Assembly (ROSA) | |

| Bidirectional Optical Subassembly (BOSA) | |

| C. Quartz/Glass Products | Quartz Rods for Sale |

| Quartz Capillary Tube | |

| Quartz Capillaries | |

| Thin Wall Glass Tubing |