Call Us

86-755-82924037

Call Us

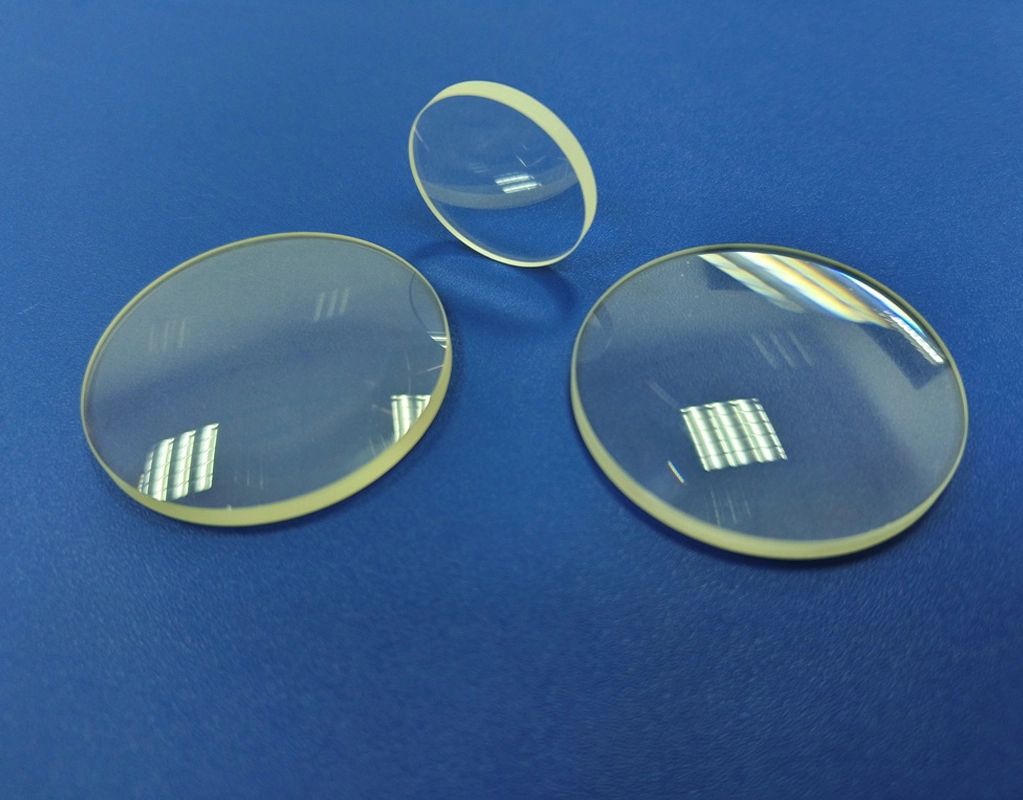

86-755-82924037The magnesium fluoride lens uses ultra-precision multi-axis free-form surface machining, followed by ultra-precision fine grinding, measurement, and polishing processes. Under precise control of the machine tool and processing environment, ultra-precision machining of the optical aspherical plastic domain is achieved. The use of ultra-precision correction polishing technology ensures the lens surface is polished to high standards. The optical aspherical surface shape accuracy is ≤0.1 micron, and the surface roughness Ra is ≤0.01 micron. This meticulous process results in a high-quality MgF2 lens suitable for infrared applications.

| Magnesium Fluoride Lenses product parameter table | |||

| Project | Indicator requirements | ||

| 1. Material | Magnesium Fluoride materials | ||

| 2. Diameter | OD≤φ150mm OD±0.025 or according to customer requirements | ||

| 3. Center thickness | T±0.01 or according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% aspheric area | ||

| 7. Coating | AR coating R<0.5% @λnm | ||

| 8. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9.Surface quality | 60-40, 40-20, 20-10 | ||

One-stop customized production: Solar Valley can process a variety of infrared lenses, flat convex, double convex, convex and concave structure aspherical Magnesium fluoride Lenses.The shape can be round, D-type, square and so on.

Material: Magnesium fluoride is tetragonal crystal system, characterized by anisotropy. Therefore, single crystals are considered in precision imaging and signal transmission. Magnesium fluoride (MgF2) is an excellent infrared optical material with a transmittance range of 0.12-10um, which is not easy to be chaotized, and a refractive index of about 1.38, which is a very excellent ultraviolet band material and the most important low-refractive index lens material.

Lens performance: CVD magnesium fluoride (MgF2-CVD) has good mechanical properties, chemical stability, impact resistance, heat wave resistance and radiation ability. Although it has excellent transmittance in the 0.11 to 9 um range, it is suitable for optical lens, wedge and window manufacturing. MgF2 is also considered to be a durable material in deep ultraviolet and long-wave infrared applications.

Product indicators:

1. The maximum external dimension of circular magnesium fluoride lens: OD≤φ150mm

2. Maximum external dimension of square magnesium fluoride lens: L×W ≤100×100mm

3. Magnesium fluoride lens can reach the following accuracy levels according to customer requirements:

Ultra-high precision: surface shape error < 0.1μm, surface roughness < 0.01μm

High precision grade: Surface error < 0.5μm, surface roughness < 0.05μm Precision grade: Surface error < 1μm, surface roughness < 0.1μm

Similar product of gallium arsenide lens is also provided for you to explore.

Surface defect grade: 60-40, 40-20, 20-10 according to customer requirements.

Coating: According to customer requirements for coating, can provide no coating or a variety of broadband anti-reflection coating options.

Magnesium fluoride lenses and windows are essential in various optical systems due to their excellent clarity and high transmission rates, particularly in the UV spectrum. These properties make them ideal for applications in astronomy, microscopy, and UV photography, where precise light transmission and minimal distortion are critical. The use of an MgF2 lens and magnesium fluoride glass in these components ensures optimal performance and superior image quality. The magnesium fluoride lens is particularly valued for its ability to maintain high transmission rates and clarity, making it a crucial element in advanced optical applications.

A magnesium fluoride coating on optical components, such as lenses and windows, significantly enhances their efficiency and durability. This coating minimizes reflections, allowing more light to pass through, which is essential for achieving high-quality images and signals in optical systems. The use of a magnesium fluoride lens and MgF2 lens ensures optimal performance. Additionally, the coating protects against scratching and environmental damage, extending the lifespan of the optical components. The incorporation of magnesium fluoride glass coatings further ensures superior clarity and long-term reliability.

| Types | Products |

| A. Optical Lenses & Components | Germanium Lens Price |

| Cemented Achromatic Doublet | |

| Magnesium Fluoride Lens | |

| Laser Lens Factory | |

| Optical Glass Prism Cube | |

| Dichroic Mirror Price | |

| UV Dome | |

| Corner Cube China | |

| B. Optical Subassemblies (TOSA/ROSA/BOSA) | Transmitter Optical Sub Assembly (TOSA) |

| Receiver Optical Sub Assembly (ROSA) | |

| Bidirectional Optical Subassembly (BOSA) | |

| C. Quartz/Glass Products | Quartz Rods for Sale |

| Quartz Capillary Tube | |

| Quartz Capillaries | |

| Thin Wall Glass Tubing |