Call Us

86-755-82924037

Call Us

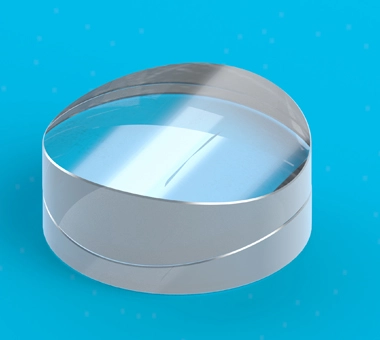

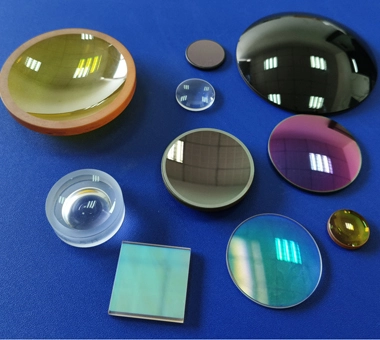

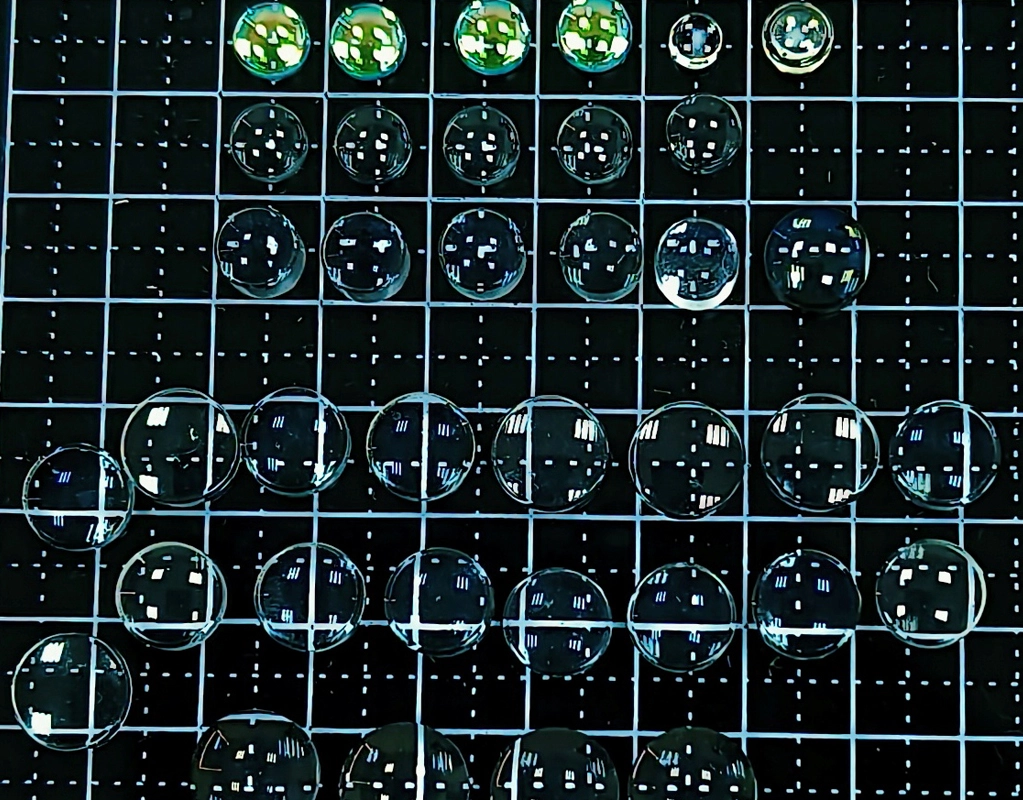

86-755-82924037Micro lens is manufactured by two processes, one is that the microlens is molded by high temperature, which has the advantages of low production cost and high precision, and is suitable for the mass production of aspherical microlenses. The second is the use of high-precision CNC machine tool fine grinding, grinding, measuring, polishing process processing and forming, suitable for optical glass, optical quartz, sapphire, infrared crystal spherical and aspherical microlens manufacturing. Microlens is the core component of a variety of optical systems, widely used in medical instruments, optical fiber transmission equipment, microimaging systems, etc. Solar Valley high-precision microlens can greatly improve the imaging effect.

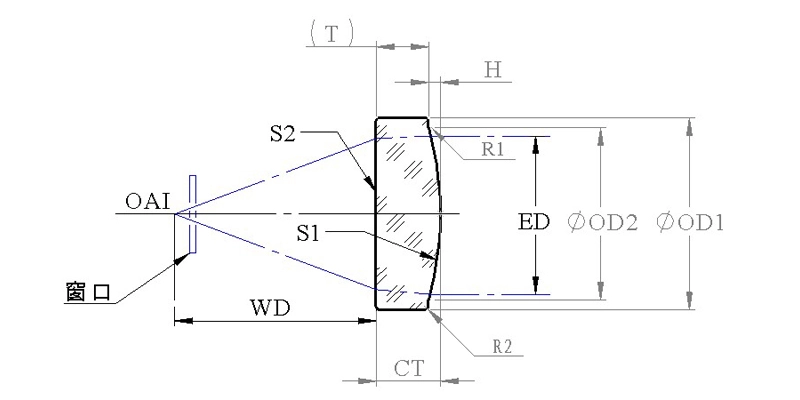

| Micro Lenses parameter table | |||

| project | Indicator requirements | ||

| 1.Material | Use optical glass, optical quartz, sapphire, infrared materials and so on | ||

| 2.Dimensions | OD≤3mm ±0.01 | ||

| 3.Center thickness | T≤2mm ±0.01 | ||

| 4.Effective focal length | according to customers needs | ||

| 5.Working distance | according to customers needs | ||

| 6.Design wavelength | 430~633nm, 630~780nm, 1550~1620nm | ||

| 7.Numerical aperture | according to customers needs | ||

| 8.Coating | AR anti-reflection coating R<0.2% @λnm | ||

| 9. Eccentricity | according to customers needs | ||

| 10. Effective aperture | ED>90% aspheric area | ||

| 11. Surface shape | Ultra-high precision Rt≤0.1μm, high-precision Rt≤0.5μm, precision Rt≤1μm | ||

| 12.Surface quality | 60-40, 40-20, 20-10 | ||

One-stop design and customized production: Solar Valley processes a variety of flat convex, double convex, convex and concave structure of microlenses according to customer requirements.

Material: Microlens materials are selected according to customer requirements, including optical glass, optical quartz, sapphire, infrared crystal and so on.

Microlens performance: high surface hardness, mechanical wear resistance, high damage threshold, long service life, uniform spot, clear projection. The transmittance of the microlens covers the whole wavelength range of visible light, ultraviolet band to mid-infrared band, and has a high transmittance. Microlens is the core component of a variety of optical systems, widely used in medical instruments, optical fiber transmission equipment, microimaging systems, etc. Solar Valley high-precision microlens can greatly improve the imaging effect.

Description of product indicators:

Maximum external dimension of microlens: microlens diameter ≤φ3mm center thickness ≤2mm

According to customer requirements, microlenses can achieve the following accuracy levels:

Ultra-high precision: surface shape error < 0.1μm, surface roughness < 0.01μm

High precision grade: Surface error < 0.5μm, surface roughness < 0.05μm Precision grade: Surface error < 1μm, surface roughness < 0.1μm

Microlens surface defect grade: 60-40, 40-20, 20-10, according to customer requirements.

Coating: coating according to customer requirements.