Call Us

86-755-82924037

Call Us

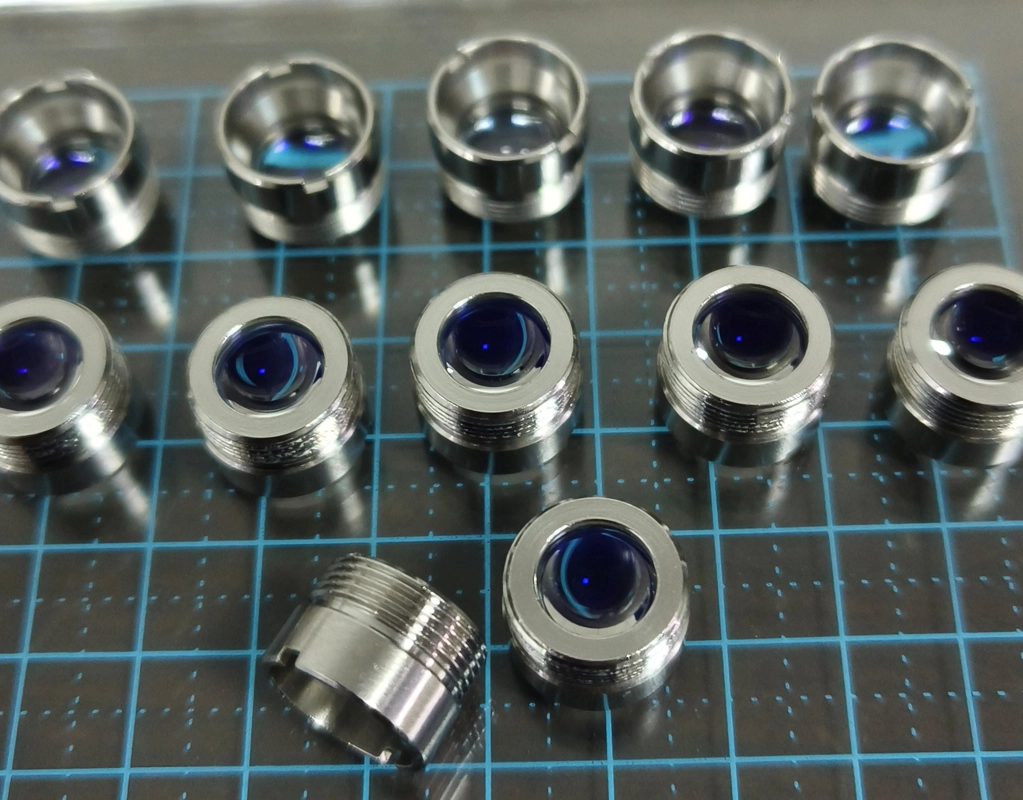

86-755-82924037MIP lens components are formed by high-temperature molding of glass glass materials and metal parts using ultra-high-precision molds under the protection of inert gas at set high temperatures and pressures to produce MIP lens components with high-precision surface shape accuracy. The advantage of MIP lens components is that they do not need to be packaged, they are molded directly at high temperatures in one go, and the lens and metal parts are solidified together. It has high sealing performance, low production cost, high precision, and is suitable for mass production. Mainly used for focusing, collimating, transmitting coupling and receiving coupling in various optical systems.

| MIP lens assembly parameter table | |||

| project | Indicator requirements | ||

| 1. Material | Including various high-temperature molded glass materials and stainless steel, SF20F and other metals | ||

| 2. Outer diameter | φ3≤OD≤φ20mm | ||

| 3. Thickness | according to customers needs | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Design wavelength | according to customers needs | ||

| 8. Coating | AR anti-reflection coating R<0.5% @λnm according to customer requirements | ||

| 9. Eccentricity | according to customers needs | ||

| 10. Effective aperture | ED>90% aspheric area | ||

| 11. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 12. Surface quality | 60-40, 40-20, 20-10 | ||

One-stop design and customized production: Solar Valley designs and high-temperature molding processes MIP lens components of various sizes and structures according to customer requirements. The optical surface of the lens can be spherical or aspherical.

Material: Solar Valley's molding materials are selected according to customer requirements, including various high-temperature molded glass materials and metal parts.

MIP lens component properties: uniform light spot, clear projection, complete specifications, aerospace quality.

Product specification description: Maximum external dimensions of MIP lens assembly: φ3≤OD≤φ20mm

MIP lens assembly can reach the following precision levels according to customer requirements: Ultra-high precision level: surface shape error <0.1μm, surface roughness <0.01μm High Precision grade: Surface error <0.5μm, surface roughness <0.05μm Precision grade: Surface error <1μm, surface roughness <0.1μm

Surface defect grade: 60-40, 40-20, 20-10, in accordance with Customers require production.

Coating: Coating according to customer requirements.