Call Us

86-755-82924037

Call Us

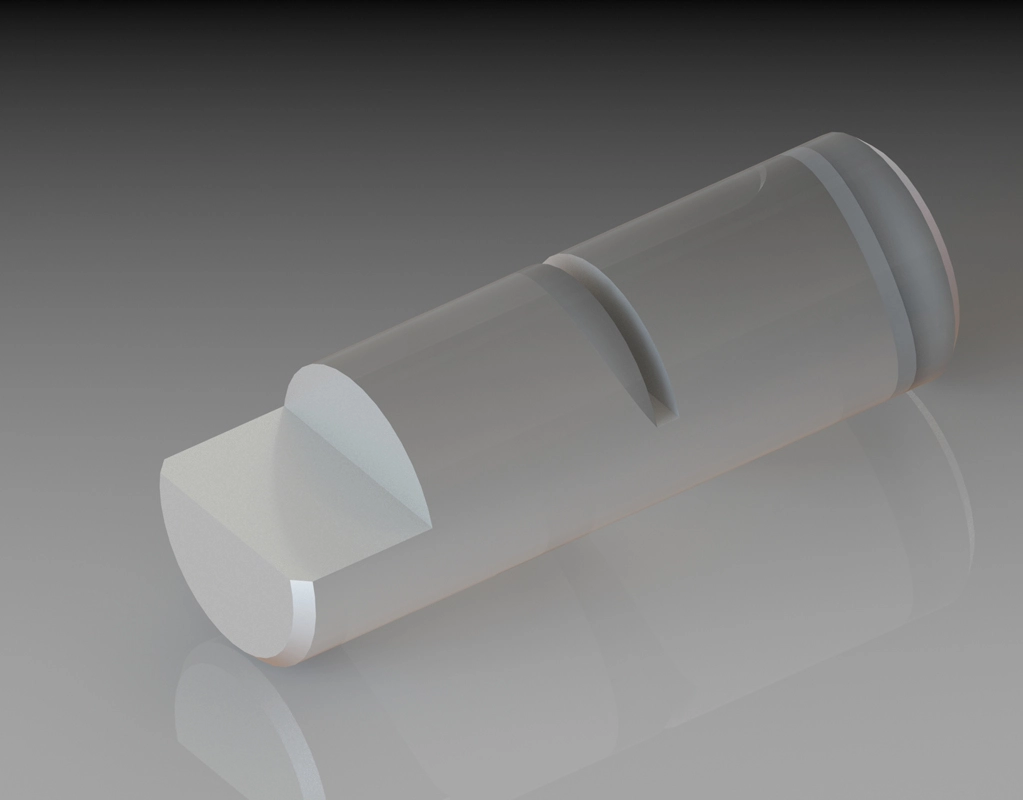

86-755-82924037Glass rod is the basic device of optical communication devices, with high dimensional accuracy, high hardness and excellent environmental tolerance. It is used in optical devices such as optical couplers, ribbon fiber welding protectors, high-power lasers, etc. The main manufacturing method is to prefabricate the glass rod, and after cleaning, it is installed on the top of the high-temperature graphite furnace and sent into the high-temperature graphite furnace core protected by inert gas. Continuous traction, wire drawing, cutting and other series of program operation, direct mass rapid production of glass rods with transparent surface, can be grinding on the surface of transparent glass rods, high dimensional accuracy, suitable for mass production, can greatly reduce the cost of parts, improve the quality of parts.

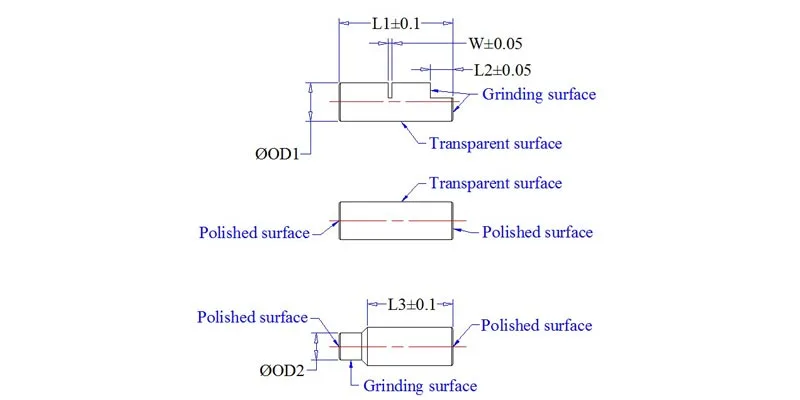

| Glass rod product parameter table | ||

| Project | Indicator requirements | |

| Material properties | Material: Borosilicate Glass | |

| Density: 2.3×10³Kg/m³ Thermal expansion coefficient: 3.3×10-6cm/cm℃ | ||

| Compressive strength: >1.57×108Pa Young’s modulus 6.76×1010Pa/m2 | ||

| Softening point: 820℃ Annealing point: 560℃ Deformation point: 520℃ | ||

| Refractive index: 1.47 | ||

| Dielectric constant: 4.9(@1MHz) | ||

| Dimensional accuracy | Outer diameter OD: φ0.5≤OD≤φ10mm | |

| Length L: L=0.5~100mm±0.2mm, the length can be processed according to customer requirements | ||

| Surface requirements | The product has no cracks, both end surfaces are ground surfaces, and the cylindrical surface is transparent. | |

Material: Borosilicate Glass, silica (SiO2) content 80%, softening point > 800℃, high strength, high hardness and high light transmittance.

Performance: The glass rod is made of high temperature melting and drawing, the surface is transparent, and the hidden micro-cracks on the local surface of the surface are eliminated. It is not easy to crack and break when the optical fiber is fixed by dispensing, and the dispensing pass rate is high.

High Ultraviolet Transmission: The glass rod is a transparent surface with high ultraviolet transmission characteristics, which can quickly cure and bond the capillary and single fiber through ultraviolet adhesive to fix and position the fiber.

Environmental Performance: The production process does not use any chemical solvents, and the material and production process does not contain or involve EU controlled substances.

High Dimensional Accuracy: Glass rods of various shapes and structures are accurately made by CNC wire drawing tower, and optical fiber dimensional tolerance and positioning accuracy are high.

Custom Structure: The use of high-precision grinding machine for fine grinding of the glass rod plane, you can customize a variety of structures to meet the requirements of optical fiber connection.