Call Us

86-755-82924037

Call Us

86-755-82924037Fused quartz windows are processed through fine grinding, grinding, measuring, ultra-high-precision polishing and other processes. Under precise control of the machine tool and processing environment, ultra-high-precision correction polishing technology is used to polish the window surface to achieve an optical plane. Fused silica windows with surface accuracy ≤0.1 micron and surface roughness Ra≤0.01 micron

| Fused quartz window product parameter table | |||

| project | Indicator requirements | ||

| 1. Material | High purity fused quartz, such as JGS1, JGS2, JGS3, etc. | ||

| 2. Diameter | OD≤300mm OD±0.025 or according to customer requirements | ||

| 3. Center thickness | T=0.1~50mm±0.01 or according to customer requirements | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% area | ||

| 7. Coating | Anti-reflection coating, reflective film R<0.5% @λnm | ||

| 8. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9. Surface quality | 60-40, 40-20, 20-10, 10-5 | ||

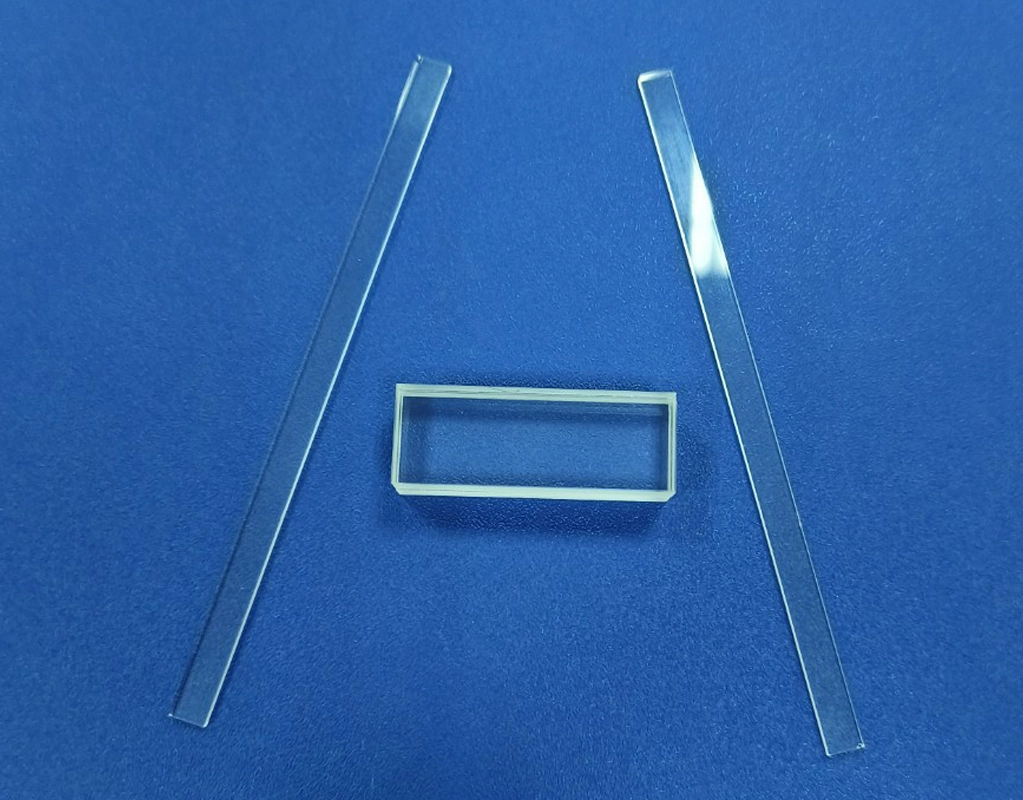

One-stop customized production: Solar Valley processes various custom optical windows, circular, D-shaped, square, trapezoidal and other structural fused quartz windows according to customer requirements, and can provide windows of different size ranges and materials. piece.

Material: Quartz has excellent physical and chemical properties, and its optical properties penetrate far ultraviolet, visible light and near-infrared spectrum. It is the best choice among all ultraviolet transparent materials. Because quartz glass is resistant to high temperatures, has a very small thermal expansion coefficient, and has good chemical stability. Its bubbles, streaks, uniformity, and birefringence are comparable to those of ordinary optical glass. Therefore, it can work in various harsh situations and has a high stability of optical coefficients. Essential optical materials.

Properties of fused silica windows: strong resistance to mechanical impact and thermal shock, high surface hardness, high transmittance, suitable for use in harsh environments. It can be made very thin and is suitable for visible light use. It is usually used as a protective window for electronic sensors or detectors of the external environment. It is used to separate the environment on both sides to isolate the inside and outside of the instrument from each other, thereby protecting the internal components. Product specification description: 1. Maximum outer dimension of fused quartz window: OD≤φ300mm, thickness 0.1~50mm 2. Maximum outer dimension: L×W ≤300×300mm 3. The following accuracy levels can be achieved according to customer requirements: Ultra-high precision level: Surface error <0.1μm, surface roughness <0.01μm High precision grade: surface error <0.5μm, surface roughness <0.05μm Precision grade: surface error <1μm, surface roughness <0.1μm

Surface defect level: 60-40, 40-20, 20-10, 10-5 are produced according to customer requirements.

Coating: Coating according to customer requirements.