Call Us

86-755-82924037

Call Us

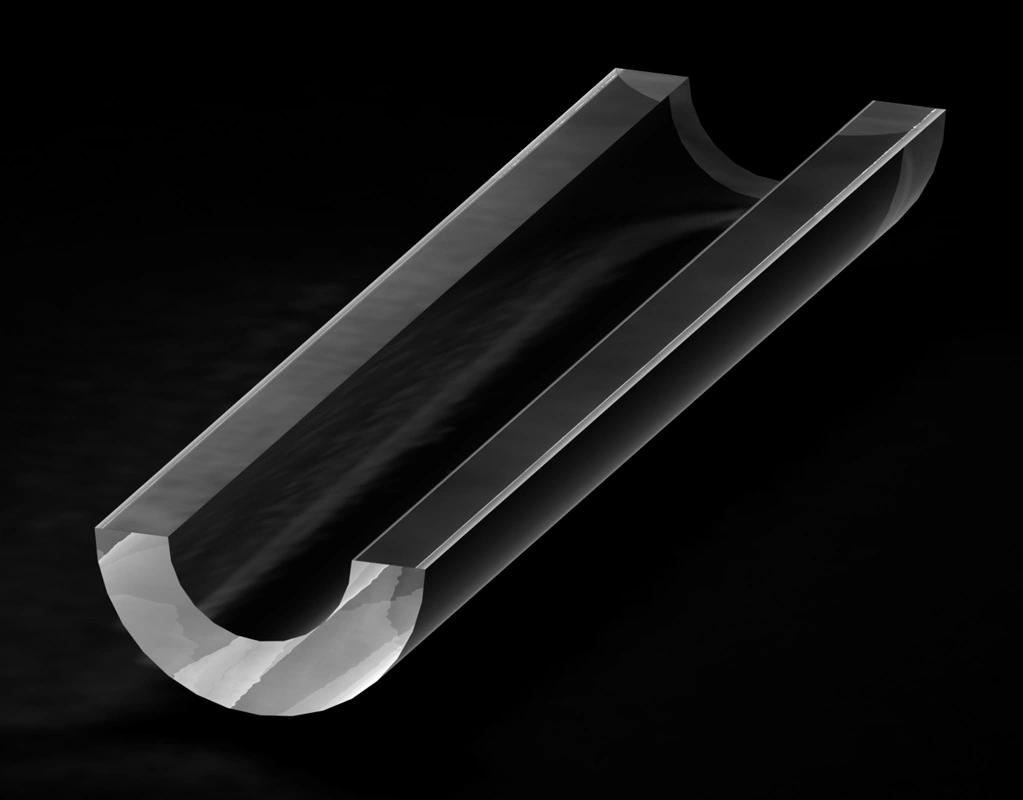

86-755-82924037Quartz Substrates - A2 serve as critical components in optical communication technologies, perfectly matched in thermal expansion to optical fibers, ensuring seamless integration. These substrates are celebrated for their exceptional dimensional precision, robustness, and outstanding resistance to environmental challenges. They find extensive applications across various optical devices, including optical couplers, ribbon fiber welding protectors, and high-power lasers. The production process begins with the meticulous cleaning of the quartz master tube, followed by its strategic placement above a high-temperature graphite furnace. Protected by inert gas, the tube undergoes continuous traction, drawing, and cutting, culminating in the grinding into a semi-round A2 structure. This sophisticated manufacturing sequence facilitates the mass production of A2 quartz substrates, characterized by their clear surfaces, superior performance, and high dimensional accuracy, all while enhancing component quality and reducing costs.

| A2 Quartz Substrate Specification Sheet | |||

| Item | Specification | ||

| Material Properties | Quartz: Purity of SiO2>99.9% | ||

| Density: 2.2×10³Kg/m³ CTE: 5.5×10-7cm/cm℃ | |||

| Compressive Strength: 4.8×107Pa (N/m²) (7000psi) | |||

| Tensile Strength: >1.1×109Pa (160000psi) | |||

| Softening Point:1683℃ Annealing Point: 1215℃ Deformation Point: 1120℃ | |||

| Refractive Index: 1.4585 | |||

| Dielectric Constant: 3.75 (@1MHz) Insulation Strength: 5×107V/m | |||

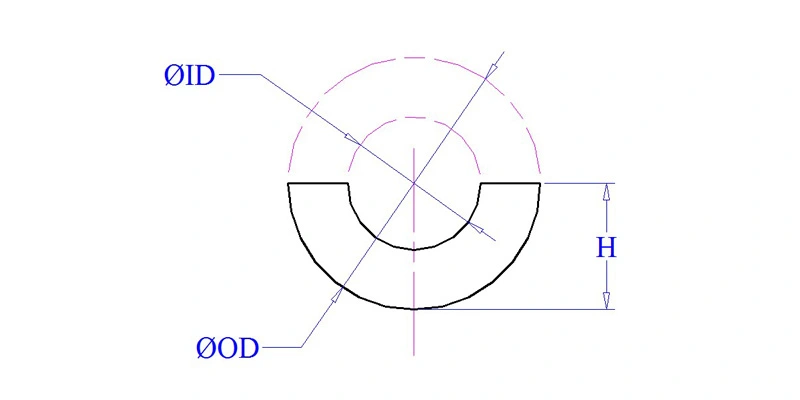

| Dimensions and Tolerances | OD: φ0.5≤OD≤φ3mm±0.1 φ3<OD≤φ10mm±0.15 | ||

| ID: φID±0.05mm according to customer requirements. | |||

| Height: H±0.05mm according to customer requirements. | |||

| Length: L=0.5~100mm±0.2mm, according to customer requirements. | |||

| Surface Quality | The product has no cracks, the two ends and the plane are grinding surfaces, and the cylindrical surface is transparent. | ||

Material: high purity fused quartz, purity of SiO2> 99.9%, softening point > 1650℃, high strength, high wear resistance, high transmittance.

Properties:The A2 quartz substrate is made of high-temperature melting and drawing, the surface is transparent, and the semi-circular plane is processed by the gas-suspended spindle CNC grinding machine, which controls the surface micro-cracks to a minimum, and the quartz substrate has high strength, which is not easy to crack and break when the optical fiber is fixed by glue.

Environmental performance: The hydraulic and electrical composite wire drawing production process does not use any chemical solvents, and the material and production process does not contain or involve the hazardous substances that forbidden in EU RoHS directive and Reach regulation.

Quality stability: Through CNC host, feeding mechanism, traction mechanism, laser rangefinder closed-loop control, can achieve accurate drawing of the required diameter and slot width of the quartz substrate,with high precision consistency, accurate optical fiber positioning slot shape, and excellent production stability.