Call Us

86-755-82924037

Call Us

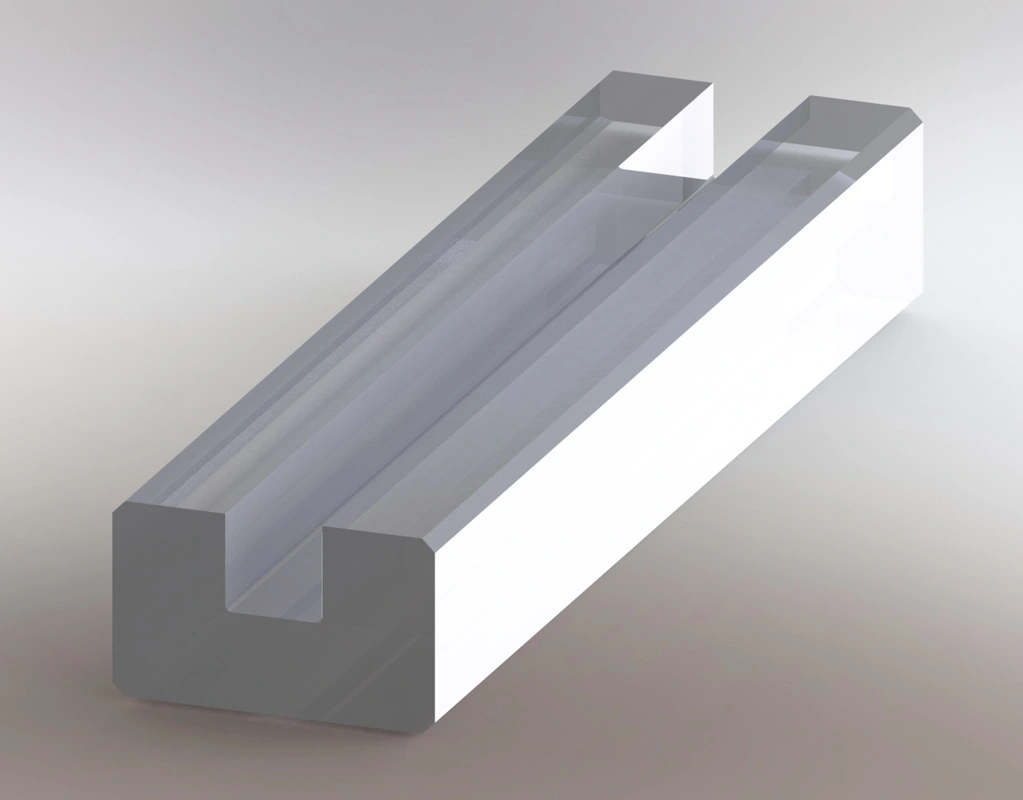

86-755-82924037Quartz Substrates - A3 are foundational components for optical communication devices, aligning perfectly with the thermal expansion properties of optical fibers to ensure optimal performance. Renowned for their high dimensional precision, exceptional hardness, and unparalleled environmental resilience, these substrates are pivotal in the manufacturing of optical couplers, ribbon fiber welding protectors, and high-power laser equipment. The fabrication process involves a meticulous procedure of double-sided grinding and polishing of quartz plates, followed by cutting into precise strips, CNC grooving, and final segmentation. This comprehensive manufacturing approach enables the production of A3 quartz substrates on a large scale, delivering products with outstanding performance, superior dimensional accuracy, and a significant enhancement in component quality, catering to the rigorous demands of advanced optical applications.

| A3 Quartz Substrate Specification Sheet | |||

| Item | Specification | ||

| Material Properties | Quartz: Purity of SiO2>99.9% | ||

| Density:2.2×10³Kg/m³ CTE: 5.5×10-7cm/cm℃ | |||

| Compressive Strength:4.8×107Pa (N/m²) (7000psi) | |||

| Tensile Strength:>1.1×109Pa (160000psi) | |||

| Softening Point:1683℃ Annealing Point:1215℃ Deformation Point:1120℃ | |||

| Refractive Index:1.4585 | |||

| Dielectric Constant:3.75 (@1MHz) Insulation Strength:5×107V/m | |||

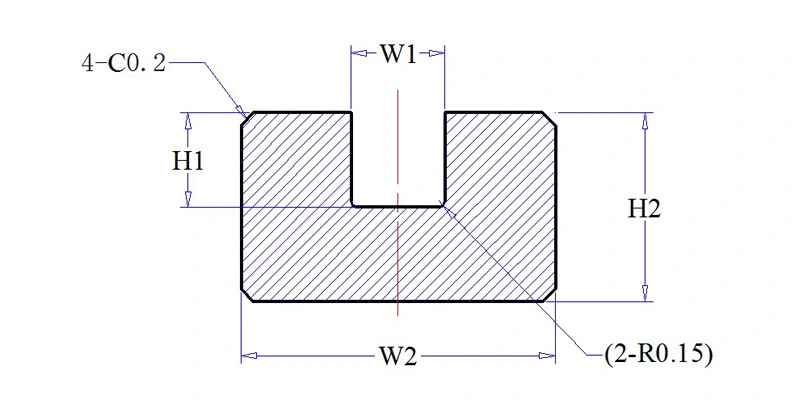

| Dimensions and Tolerances | Width W1:φ0.5≤OD≤φ3±0.05mm,φ3≤OD≤φ10mm±0.1mm. | ||

| Width W2:φ0.5≤OD≤φ3±0.05mm,φ3≤OD≤φ10mm±0.1mm. | |||

| Depth:H1 0.2≤OD≤8±0.1mm, or according to customer requirements. | |||

| Hight H2:H±0.1mm, or according to customer requirements. | |||

| Length:L=1~300mm±0.2mm, or according to customer requirements. | |||

| Arc Angle R:slot bottom process rounded angle,R≤0.15mm | |||

| Chamfer: Protective chamfer C0.2 can be made according to customer requirements. | |||

| Surface Quality | The product has no cracks, the two end faces, sides and straight grooves are grinding surfaces, and the upper and lower surfaces of the thickness are transparent surfaces. | ||

| Matched cover can be produced according to customer requirements. | |||

Material: high purity fused silica, purity of SiO2> 99.9%, softening point > 1650℃, high strength, high wear resistance, high transmittance.

Properties: The quartz substrate is processed by the pneumatic suspension spindle CNC grinding machine, which controls the surface micro-cracks to a minimum. The quartz substrate has high strength, and is not easy to crack and break when dispensing fixed fiber, and the dispensing pass rate is high.

Environmental performance: CNC grinding production process does not use any chemical solvents, materials and production processes do not contain or do not involve the hazardous substances that forbidden in EU RoHS directive and Reach regulation.

Quality stability: The quartz substrate precisely ground by the CNC machine has very high precision consistency, accurate shape of the optical fiber positioning slot, and excellent production stability.

Matched cover: We can produce double-sided transparent quartz cover of various thicknesses according to customer requirements.