Call Us

86-755-82924037

Call Us

86-755-82924037Quartz Substrates - A6 are pivotal for the advancement of optical communication technologies, closely mirroring the thermal expansion rate of optical fibers to ensure optimal compatibility and performance. These substrates are celebrated for their unparalleled dimensional precision, durability, and superior resistance to environmental conditions, making them indispensable in the development of optical couplers, ribbon fiber fusion splicers, and high-power laser devices. The manufacturing journey of A6 substrates begins with a carefully prefabricated quartz rod, which, after undergoing a thorough cleaning process, is strategically positioned above a high-temperature graphite furnace. Within this furnace, shielded by an inert gas atmosphere, the rod is meticulously processed through continuous traction, drawing, cutting, and a sequence of finely tuned operations. This methodical approach enables the efficient production of A6 quartz substrates on a grand scale, characterized by their crystal-clear surfaces and exceptional dimensional accuracy. Such a streamlined production process not only significantly lowers the cost of components but also substantially elevates their quality, making A6 substrates a cornerstone for mass-produced, high-quality optical communication devices.

| A6 quartz substrate product parameter table | |||

| Item | Specification | ||

| Material Properties | Quartz Quartz, Silicon Dioxide (SiO2) content>99.9% | ||

| Density: 2.2×10³Kg/m³ Thermal expansion coefficient: 5.5×10-7cm/cm℃ | |||

| Compressive strength: 4.8×107 Pa (N/m²) (7000psi) | |||

| Tensile strength: >1.1×109 Pa (160000psi) | |||

| Softening point: 1683℃ Annealing point: 1215℃ Deformation point: 1120℃ | |||

| Refractive index: 1.4585 | |||

| Dielectric constant: 3.75 (@1MHz) Insulation strength: 5×107V/m | |||

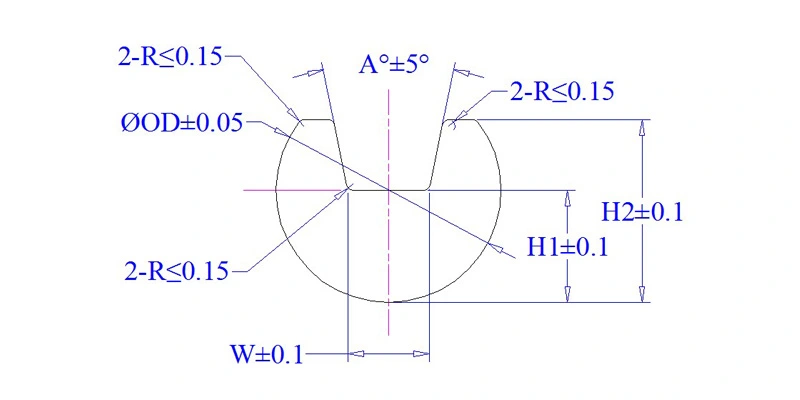

| Dimensions and Tolerances | Outer diameter OD: φ0.5≤OD≤φ3±0.05mm, φ3≤OD≤φ5mm±0.1mm | ||

| Slot width W: W 0.2≤OD≤4±0.1mm or according to customer requirements | |||

| Back height H1: H is 1/2 of the outer diameter, H=OD/2±0.1mm or according to customer requirements | |||

| Total height H2: H2±0.1mm according to customer requirements | |||

| Angle A: Choose 23°±5° or 28°±5° according to the groove width. | |||

| Arc angle R: rounded corner by high temperature drawing process, R≤0.15mm | |||

| Length L: L=1~100mm±0.2mm, the length can be processed according to customer requirements | |||

| Surface Quality | The product has no cracks, both end surfaces are ground surfaces, and the cylindrical surface and groove surface are transparent surfaces. | ||

| If customers have special requirements, surface etching and frosting can be performed | |||

Material: High-purity fused quartz, with a silicon dioxide (SiO2) content of >99.9%. Softening point >1650°C, high strength, high wear resistance, and high light transmittance.

Properties: The quartz substrate is produced through high-temperature melting and drawing, resulting in a transparent surface. This process eliminates localized surface microcracks and optical fiber positioning groove surface imperfections. The quartz substrate has high strength, making it resistant to cracking or shattering when fixing optical fibers with adhesive. It achieves a high pass rate for adhesive bonding.

Environmental Performance: The water, electricity, and gas composite drawing production process does not use any chemical solvents. The material and production process do not contain or involve substances controlled by the EU RoHS directive and Reach regulations.

Quality Stability: Through CNC mainframe, feeding mechanism, traction mechanism, and laser rangefinder closed-loop control, the quartz substrate with the required diameter and groove width is precisely drawn. The consistency in accuracy is very high, and the shape of the optical fiber positioning groove is accurate, ensuring outstanding production stability.