Call Us

86-755-82924037

Call Us

86-755-82924037Quartz Substrates - A7 are integral to optical communication, matching optical fibers in thermal expansion, ensuring seamless device integration. Known for their precise dimensions, durability, and environmental resilience, they’re crucial in optical couplers, fusion splicers, and lasers. Manufactured from prefabricated quartz rods, cleaned and processed in a high-temperature, inert gas-protected graphite furnace, they undergo traction, drawing, and cutting, enabling large-scale, cost-effective production. A7 substrates’ transparent surfaces and accuracy make them ideal for enhancing the quality and reducing the costs of optical components.

| A7 quartz substrate product parameter table | |||

| Item | Specification | ||

| Material Properties | Quartz Quartz, Silicon Dioxide (SiO2) content>99.9% | ||

| Density: 2.2×10³Kg/m³ Thermal expansion coefficient: 5.5×10-7cm/cm℃ | |||

| Compressive strength: 4.8×107 Pa (N/m²) (7000psi) | |||

| Tensile strength: >1.1×109 Pa (160000psi) | |||

| Softening point: 1683℃ Annealing point: 1215℃ Deformation point: 1120℃ | |||

| Refractive index: 1.4585 | |||

| Dielectric constant: 3.75 (@1MHz) Insulation strength: 5×107V/m | |||

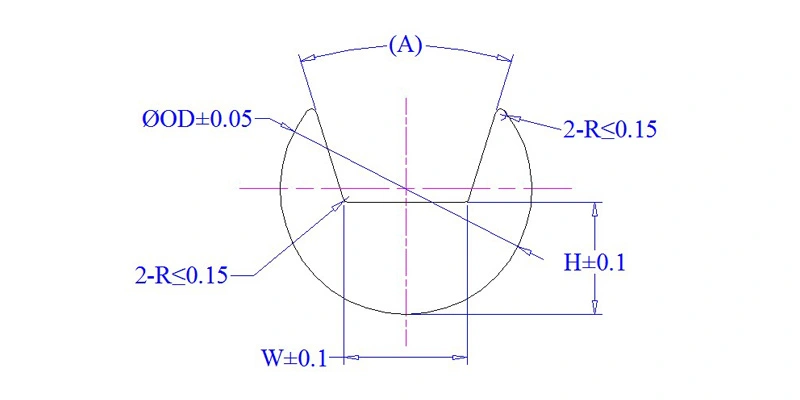

| Dimensions and Tolerances | Outer diameter OD: φ0.5≤OD≤φ3±0.05mm, φ3≤OD≤φ5mm±0.1mm | ||

| Slot width W: W 0.2≤OD≤4±0.1mm or according to customer requirements | |||

| Back height H: H±0.1mm according to customer requirements | |||

| Angle A: Choose 33° or 50° according to the groove width (the angle is a reference value) | |||

| Arc angle R: rounded corner by high temperature drawing process, R≤0.15mm | |||

| Length L: L=1~100mm±0.2mm, the length can be processed according to customer requirements | |||

| Surface Quality | The product has no cracks, both end surfaces are ground surfaces, and the cylindrical surface and groove surface are transparent surfaces. | ||

| If customers have special requirements, surface etching and frosting can be performed | |||

Material: High-purity fused quartz, with a silicon dioxide (SiO2) content of >99.9%. Softening point >1650°C, high strength, high wear resistance, and high light transmittance.

Properties: The quartz substrate is produced through high-temperature melting and drawing, resulting in a transparent surface. This process eliminates localized surface microcracks and optical fiber positioning groove surface imperfections. The quartz substrate has high strength, making it resistant to cracking or shattering when fixing optical fibers with adhesive. It achieves a high pass rate for adhesive bonding.

Environmental Performance: The water, electricity, and gas composite drawing production process does not use any chemical solvents. The material and production process do not contain or involve substances controlled by the EU RoHS directive and Reach regulations.

Quality Stability: Through CNC mainframe, feeding mechanism, traction mechanism, and laser rangefinder closed-loop control, the quartz substrate with the required diameter and groove width is precisely drawn. The consistency in accuracy is very high, and the shape of the optical fiber positioning groove is accurate, ensuring outstanding production stability.