Call Us

86-755-82924037

Call Us

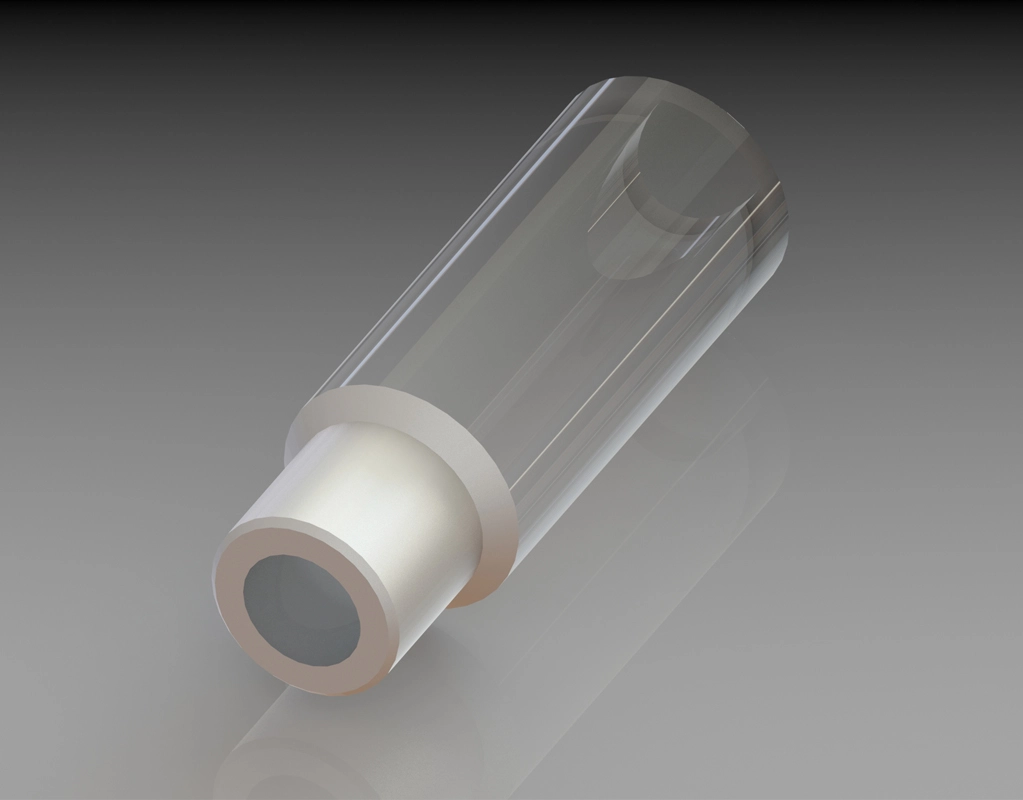

86-755-82924037Quartz tube is the basic structural component of optical communication devices. It has small size, high precision, high hardness, and excellent environmental resistance. It is used in the connection and fixation of optical devices such as optical collimators, isolators, high-power lasers, etc. Its main manufacturing method is to prefabricate the quartz mother tube. After cleaning, it is clamped above the high-temperature graphite furnace and sent into the heart of the high-temperature graphite furnace protected by inert gas. It performs a series of program operations such as continuous pulling, drawing, and cutting, etc., directly It can quickly produce small-diameter quartz tubes with transparent surfaces in large quantities, with high dimensional accuracy and is suitable for mass production. It can significantly reduce component costs and improve component quality.

| Large diameter quartz tube product parameter table | |||

| project | Indicator requirements | ||

| Material properties | Quartz Quartz, Silicon Dioxide (SiO2) content>99.9% | ||

| Density: 2.2×10³Kg/m³ Thermal expansion coefficient: 5.5×10-7cm/cm℃ | |||

| Compressive strength: 4.8×107 Pa (N/m²) (7000psi) | |||

| Tensile strength: >1.1×109 Pa (160000psi) | |||

| Softening point: 1683℃ Annealing point: 1215℃ Deformation point: 1120℃ | |||

| Refractive index: 1.4585 | |||

| Dielectric constant: 3.75 (@1MHz) Insulation strength: 5×107V/m | |||

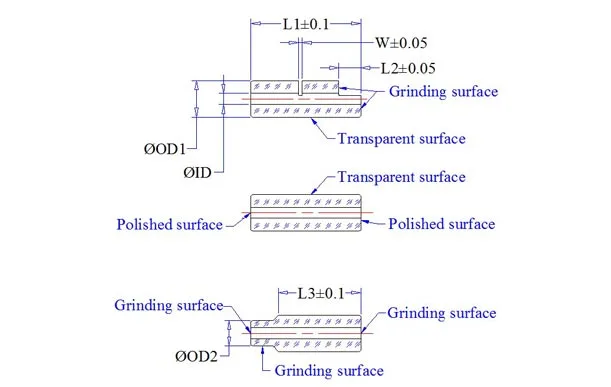

| Dimensional accuracy | Outer diameter OD: φ3<OD≤φ10mm or customized according to customer requirements | ||

| Recommended outer diameter: φ3, φ3.5, φ4, φ4.6, φ5, φ8, φ10---- | |||

| Outer diameter tolerance: OD±0.1mm, OD±0.15mm, OD±0.20mm, or customized according to customer requirements | |||

| Recommended inner diameter: Φ1.01, Φ1.51, Φ1.81, Φ2.215, Φ3.5, Φ5---- | |||

| Inner diameter tolerance: ID±0.05mm, ID±0.10mm, or customized according to customer requirements | |||

| Length L: L=0.5~300mm±0.2mm, the length can be processed according to customer requirements | |||

| surface requirements | The product has no cracks, both end surfaces are ground surfaces, and the cylindrical surface is transparent. | ||

Material: high-purity fused quartz, silicon dioxide (SiO2) content >99.9%, softening point >1650°C, high strength, high wear resistance, high light transmittance.

Usage Properties: The quartz tube is melted and drawn at high temperature. The surface is transparent, which eliminates surface micro-cracks and local surface hidden cracks in the optical fiber positioning holes. The quartz tube has high strength and is not easy to crack and break when dispensing glue to fix the optical fiber. The dispensing is qualified. The rate is high.

Environmental Properties: The hydroelectric composite wire drawing production process does not use any chemical solvents, and the material and production process do not contain or involve controlled substances required by the EU RoHS directive and Reach regulations.

Quality Stability: Through the closed-loop control of the CNC host, feeding mechanism, traction mechanism, and laser rangefinder, quartz tubes with the required diameter and inner diameter can be accurately drawn. The precision consistency is very high and the production stability is excellent.

Customized Structure: Using a high-precision grinder to finely grind the quartz tube plane, various structures can be customized to meet the requirements for connecting and fixing optical devices.