Call Us

86-755-82924037

Call Us

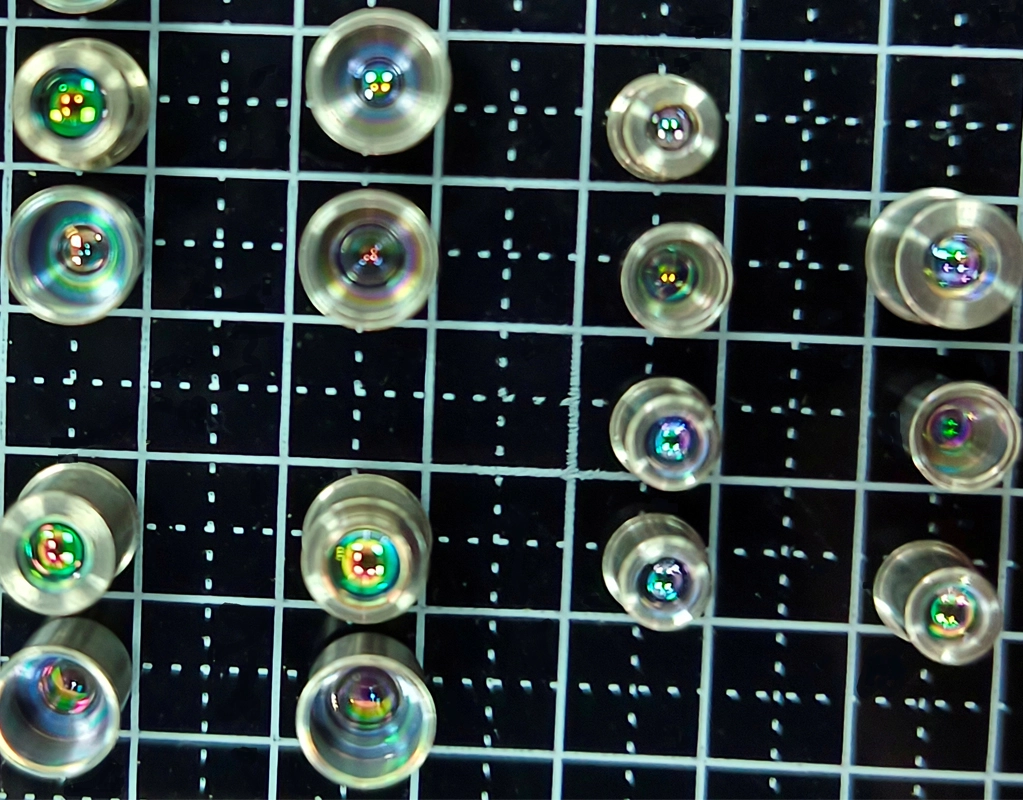

86-755-82924037TOSA transmitter optical sub assembly is mainly composed of a laser, a tube sleeve and an adapter, as well as an isolator and a regulating ring in a long-distance optical module, with a light source (semiconductor light-emitting diode or laser diode) as the core. The LD chip, monitoring photodiode (MD) and lens assembly are packaged in a compact structure (TO coaxial package or butterfly package), and the transmitter optical subassembly is mainly used for converting electrical signals into optical signals (E/O conversion). The TOSA transmitter optical subassembly usually encapsulates a microlens in a coaxial metal shell. Microlens using high temperature molding, the advantages are low production cost, high precision, suitable for aspherical microlens mass production. The transmitter optical sub assembly is one of the core components of a variety of optical systems, mainly for the conversion of electrical signals into optical signals (E/O conversion).

| TOSA Transmitter Optical Subassembly Parameter Table | |||

| project | Indicator requirements | ||

| 1. Material | Use various high and low refractive index optical glass and stainless steel, SF20F and other metal housings | ||

| 2. Outer diameter | Round OD≤20mm | ||

| 3. Thickness | according to customers needs | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Design wavelength | according to customers needs | ||

| 8. Coating | AR anti-reflection coating R<0.5% @λnm according to customer requirements | ||

| 9. Eccentricity | according to customers needs | ||

| 10. Effective aperture | ED>90% aspheric area | ||

| 11. Surface shape | Ultra-high precision Rt≤0.1μm, high precision Rt≤0.5μm, precision Rt≤1μm | ||

| 12.Surface quality | 60-40, 40-20, 20-10, 10-5 | ||

One-stop customized production: Solar Valley processes TO CAN laser diode of various sizes and structures according to customer requirements, and the optical surface of the lens can be spherical and aspherical.

Transmitter Optical Subassembly Material: Use a variety of high and low refractive index optical glass and metal material coaxial shell.

TOSA transmitter optical sub assembly performance: Solar Valley strictly matches TOSA transmitter optical subassembly diameter and center thickness to ensure package quality and high precision required center thickness. Using various packaging technologies such as UV curing, gluing and high temperature powder curing in different glass and metal coaxial housings, Solar Valley accurately controls the focal length and various optical properties of TOSA lens components.

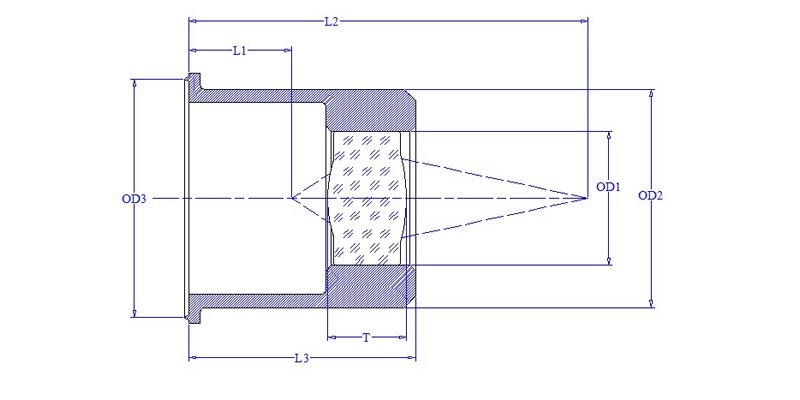

Transmitter Optical Subassembly Product size indicator description:

TOSA transmitter optical subassembly maximum dimensions: OD≤φ20mm

TOSA transmitter optical sub assemblies can achieve the following accuracy levels according to customer requirements:

Ultra-high precision: surface shape error < 0.1μm, surface roughness < 0.01μm

High precision grade: Surface error < 0.5μm, surface roughness < 0.05μm Precision grade: Surface error < 1μm, surface roughness < 0.1μm

Transmitter Optical Subassembly Surface defect grade: 60-40, 40-20, 20-10, 10-5 According to customer requirements.

Transmitter Optical Subassembly Coating: Coating according to customer requirements.

| Types | Products |

| A. Optical Lenses & Components | Germanium Lens Price |

| Cemented Achromatic Doublet | |

| Magnesium Fluoride Lens | |

| Laser Lens Factory | |

| Optical Glass Prism Cube | |

| Dichroic Mirror Price | |

| UV Dome | |

| Corner Cube China | |

| B. Optical Subassemblies (TOSA/ROSA/BOSA) | Transmitter Optical Sub Assembly (TOSA) |

| Receiver Optical Sub Assembly (ROSA) | |

| Bidirectional Optical Subassembly (BOSA) | |

| C. Quartz/Glass Products | Quartz Rods for Sale |

| Quartz Capillary Tube | |

| Quartz Capillaries | |

| Thin Wall Glass Tubing |