Call Us

86-755-82924037

Call Us

86-755-82924037Zinc Selenide lens uses a single point diamond ultra-precision multi-axis free-form surface machining machine, after ultra-precision single point turning, grinding, measurement, ultra-precision polishing and other processes, the lens accuracy can be less than 0.05 microns. Under the condition of precise control of the machine tool and processing environment, the optical aspherical plastic domain ultra-precision machining is achieved. The ultra-high precision correction polishing technology is used to polish the lens surface, and the optical aspherical surface shape accuracy is less than 0.1 micron, and the surface roughness Ra is less than 0.01 micron.

| Zinc Selenide Lenses product parameter table | |||

| Project | Indicator requirements | ||

| 1. Material | Zinc Selenide | ||

| 2. Diameter | OD≤φ300mm OD±0.025 or according to customers needs | ||

| 3. Center thickness | CT±0.01 or according to customers needs | ||

| 4. Effective focal length | according to customers needs | ||

| 5. Working distance | according to customers needs | ||

| 6. Effective aperture | ED>80% aspheric area | ||

| 7. Coating | AR R<0.5% @λnm | ||

| 8. Surface shape | Ultra high precision Rt≤0.1μm,High precision Rt≤0.5μm, precision Rt≤1μm | ||

| 9.Surface quality | 60-40, 40-20, 20-10 | ||

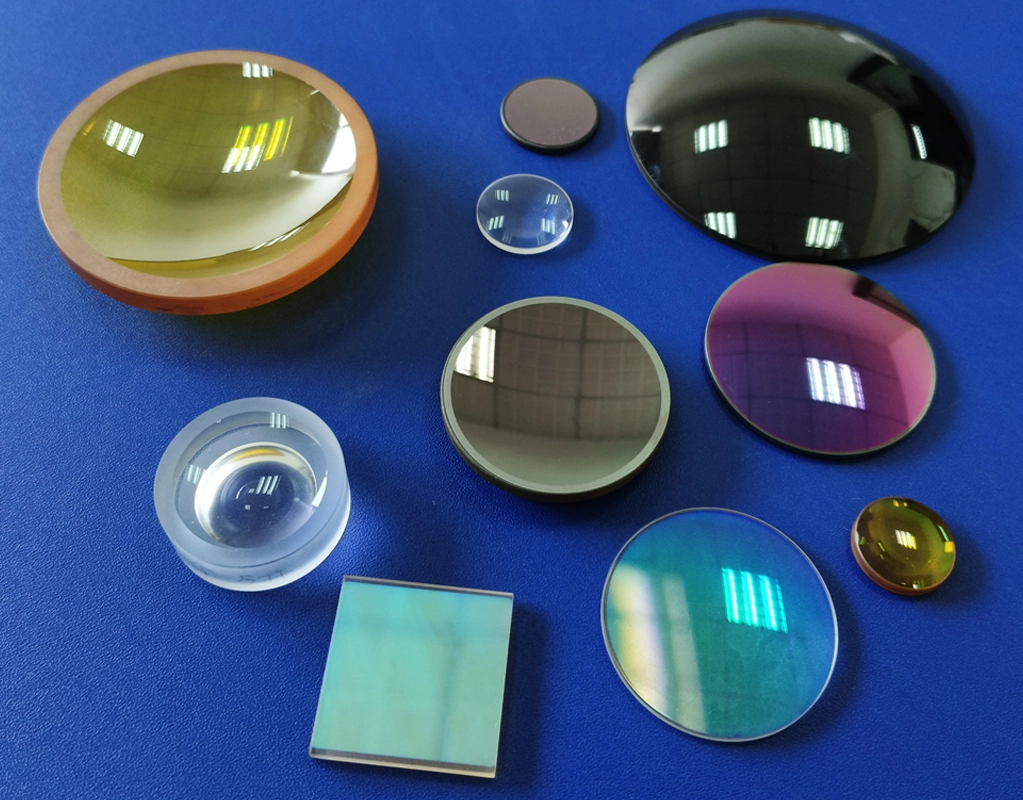

One-stop customized production: Solar Valley processes various infrared lenses, plano-convex, biconvex, and convex-concave structure Zinc Selenide lenses according to customer requirements. The lens shape can be circular, D-shaped, square, trapezoidal, etc.

Material: Zinc selenide has low absorption to infrared wavelengths and can transmit visible light, which is the preferred material for making infrared lenses, windows, output coupling mirrors and beam expanding mirrors.

Lens properties:Zinc selenide has very good transmittance in the 0.5-22μm, especially 10.6μm band, and is often used in thermal imaging and FLIR systems. Its excellent low absorption coefficient and high thermal shock resistance make it ideal for high-power CO2 laser applications. Zinc selenide (ZnSe) plano-convex (PCX) lenses are designed for focusing or collimating applications in medium and long wave infrared spectroscopy.

Product indicators:

1. Maximum external dimension of circular zinc selenide lens: OD≤φ300mm

2. Maximum external dimension of square zinc selenide lens: L×W ≤200×200mm

3. Zinc selenide lens can reach the following accuracy levels according to customer requirements:

Ultra-high precision: surface shape error < 0.1μm, surface roughness < 0.01μm

High precision grade: Surface error < 0.5μm, surface roughness < 0.05μm Precision grade: Surface error < 1μm, surface roughness < 0.1μm

Similar product of GaAs lens is also provided for you to explore.

Surface defect grade: 60-40, 40-20, 20-10 according to customer requirements.

Coating: According to customer requirements for coating, can provide no coating or a variety of broadband anti-reflection coating options.

Zinc Selenide (ZnSe) lenses are widely used in various optical applications, particularly in infrared (IR) systems. One of the primary applications of ZnSe lenses is in CO2 laser systems, where they serve as critical components for laser cutting, welding, and engraving. Their broad transmission range, from visible to infrared (0.5-22 µm), makes them suitable for thermal imaging, spectroscopy, and other IR applications.

ZnSe lenses are also essential in medical equipment, such as IR imaging devices and thermal cameras, where they facilitate precise imaging and diagnostics. Additionally, they are used in scientific research for spectroscopy and remote sensing, benefiting from their low absorption coefficient and high resistance to thermal shock, which ensures durability and reliability even under high-power laser conditions.

The advantages of ZnSe lenses include their exceptional optical clarity and low absorption in the IR spectrum, which results in minimal loss of laser power and higher efficiency in laser applications. Their low dispersion and high thermal conductivity allow them to maintain performance stability over a wide temperature range. Furthermore, ZnSe lenses are chemically inert and resistant to most harsh chemicals, enhancing their longevity and performance in demanding environments.